A handful of good higher precision grinding pictures I identified:

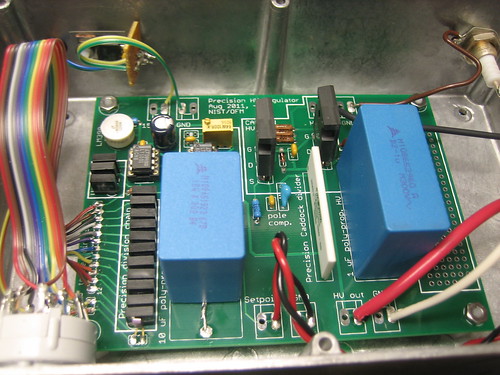

~1kV adjustable voltage source with sub-ppm stability

Image by fatllama

A industrial higher voltage source had noise and 1/f jitter that restricted its stability to .01% over almost all timescales. I wanted it to be 100 instances far better specifically over averaging occasions of .1 – 100s. I didn’t want to just add a massive RC filter, since we also require great regulation at the load and reasonable settling occasions amongst frequent switches. So, it was time to style and implement a voltage regulator. Fortunately, the circuit will have to supply barely any current the load will be the 10M of a voltage meter, and the charging currents of two electrodes amounting to 30pF of capacitance.

Here’s the simple concept: we stably divide a high voltage by one hundred and examine it to a -10V setpoint. Any errors are actively nulled by feedback to the high voltage level. Fairly a bit was inspired or shamelessly stolen from Horowitz and Hill, pp. 368-376.

A buried zener diode reference (LM399) creates a really steady ~7 V. Soon after a day of warming up, I’ve seen the fractional stability of the LM399 at least as very good as 4e-7 (1-1000 seconds). A low voltage-noise and input-offset op-amp (LT1001) converts this to ~10 V using a gain network of .2 ppm/°C Vishay resistors. The 10V is divided (more Vishay resistors) in 11 stages each stage goes to a tap on a 12-position rotary switch. This lets us pick a setpoint from amongst 11 evenly spaced voltages amongst ground and the stable 10 V reference.

The selected setpoint is RC-filtered with a polypropylene capacitor (Horowitz and Hill recommend polypropylene due to its low leakage… a alter in the leakage of .5nA would mean—heavens!—a complete ppm voltage drop in the 20kOhm filter resistance).

Meanwhile, higher voltage is applied to the the drain of an n-MOSFET featuring a very higher breakdown voltage. The supply ("output") of the MOSFET is low-pass filtered with one more polypropylene capacitor (giant blue box, above), and sees a precision 100:1 voltage divider (Caddock). Certain, a voltage divider is just two stinking resistors, but the Caddock divider delivers a division ratio with really low temperature dependence and higher stability. As a result, the top resistor is made to be very Ohmic with higher voltage applied, and the two resistors are mounted on a typical heat-sunk ceramic package. They claim a ratio tempco of 5ppm/°C.

The divided output is compared with the selected setpoint by a low-noise op amp, and the amplified "error" is sent to the gate of the MOSFET. Since the low-voltage op amp can not directly drive the high voltage pass-transistor (the gate wants to be many volts above the supply, and the supply could be at 1kV!), a second HV MOSFET acts like a voltage amplifier.

In this configuration, the MOSFETs need a bit of "overhead" the applied HV should be about 10V higher than the "output" HV. And, this overhead can be produced as higher as 700 V or so ahead of the quiescent existing through the amplifier MOSFET gets to be 1mA or so.

The exterior of the box is lined with kapton-film heaters and insulation. A thermistor is buried in the aluminum and an AD590 absolute temperature sensor is mounted on the PCB subsequent to the Vishay division resistors. A temperature controller servos the box temperature to significantly greater than 1°C stability.

If you wanted to get truly fancy, the division chain and 12-position switch could be replaced with a hugely-stabilized DAC, driven by the good 10V reference here. Then, a 12-bit digital word could generate thousands of possible "setpoints" for the HV.

20150827-NRCS-LSC-0542

Image by USDAgov

Virtual Panorama of Reiter Berry Farms, in Watsonville, CA, on Thursday, August 27, 2015, are working with the U.S. Division of Agriculture (USDA) All-natural Resources Conservation Service (NRCS) to enhance on the 30% water savings they already attain with precision micro subsurface irrigation. The use of a Wireless Irrigation Monitoring Network (WIN) to collects data from wireless solar powered soil tensiometers, and climate field stations positioned throughout farms in 3 counties allow them to track soil, temperature, and humidity circumstances with a cloud-primarily based irrigation management program, to much better handle watering and soil conservation efforts in far more than 700 acres. They actively share their data, methods, and experiences with other producers. Much better management by producers using a presently dwindling provide and quality of ground water (wells) in this county will assist recharge the aquifer and avoid the migration of nearby Pacific Ocean salt water into the ground water they use. This is 1 of the approaches growers are extending the water provide. Reiter Affiliated Firms (RAC) has been involved with household farming because 1868 is a major fresh, multi-berry producer in the planet and a leading supplier of fresh strawberries, raspberries, blueberries and blackberries in North America.

Wireless soil tensiometer are buried at multiple distinct distances and depths from the subsurface water emitters and the root balls. The tensiometer measures how strongly the soil absorbs water. The tensiometer’s porous probe is buried into the soil and a pump pulls some air out, creating a vacuum. Water and moisture from the surrounding soil enters the probe. Low amounts of water entering the tensiometer indicate plants (and evaporation) are pulling water from the soil and may require to be watered. Higher levels of water entering the tensiometer indicate the plants have enough water. This data is then transmitted to a company’s cloud-based irrigation management technique that tends to make the data available on customer’s mobile device in the field. If this information is combined with historical information and other information, it can support figure out when, how extended and how fast watering requirements to be for best efficiency, soil wellness and electrical economy to increase a business’s yield and profitability. These measurements helps ensure perfect watering and for soil conservation. The farms have been using the tensiometers for five years. USDA Photo Illustration by Lance Cheung.