Our machining capabilities have been extended with the addition of two brand new HAAS VF3 vertical Milling Vertical Centers, Machine Specifications are 40″ x 2…

Video Rating: five / five

Month: September 2014

MI: “Fab Lab” Facilitates Sophisticated Machining Education

MI: “Fab Lab” Facilitates Advanced Machining Education

Unveiled to the public at a ribbon-cutting ceremony in Petoskey this past spring, the Fab Lab consists of 12 state-of-the-art computer systems loaded with SURFCAM and AutoCAD design programs, a lathe-turning center, and milling equipment. Inspired by a similar …

Read much more on Watchdog Wire

HEIDENHAIN's TNC 640 Handle – For Milling and Turning Machines

With the TNC 640 handle, turning operations can now be enabled on a milling machine permitting the operator to transition from Milling to Turning cycles in the same plan. The turning operations can be programmed in plain text, just like the familiar …

Read much more on Marketwired (press release)

Lastest Electrical Discharge Machining Edm News

Rockwell and Fanuc announce global collab…

Robomachines are Fanuc's robotic machining centres, which include injection moulding, vertical milling and EDM (electrical discharge machining) systems. The principal initial impact of the new collaboration is expected be in the automotive market, exactly where …

Read a lot more on Drives & Controls

IMTS 2014 Conference: Re-evaluating the EDM Method

Until lately, numerous manufacturers of titanium elements have regarded as electrical discharge machining (EDM), either fully off limits, or to be employed as a principal process coupled with a secondary operation. Several instances, the secondary operation is …

Study a lot more on Today’s Power Options

Frees celebrates 58 years at Frankfort Manufacturing

He was one of the company's 1st employees trained on electrical discharge machining, or creating items employing sparks, in the 1960s. Most of his perform relies on those EDM machines, but Frees is the first to volunteer when a job requires old-fashioned …

Study far more on Traverse City Record Eagle

Good Wire Cutting images

A few nice wire cutting photos I discovered:

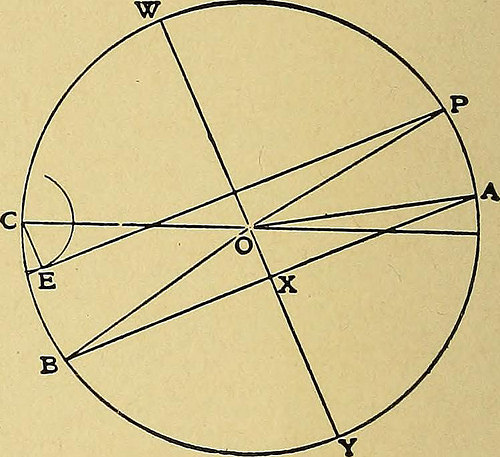

Image from page 33 of “Valve setting: simple methods of setting the plain slide valve. Meyer reduce-off. Corliss. and poppet varieties” (1908)

Image by Web Archive Book Images

Identifier: valvesettingsimp00coll

Title: Valve setting: basic methods of setting the plain slide valve. Meyer cut-off. Corliss. and poppet kinds

Year: 1908 (1900s)

Authors: Collins, Hubert Edwin, 1872-

Subjects: Steam-engines

Publisher: New York [etc.] Hill publishing organization

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Images From Book

Click right here to view book on the web to see this illustration in context in a browseable on-line version of this book.

Text Appearing Before Image:

Text Appearing Soon after Image:

FIG. 20. FIG. 21. finish the diagram by drawing in the other valve circle and the two lapcircles, and laying off on the crank circle the points corresponding to theother valve movements. Problem V. Offered the cut-off, release, compression, and width ofport. It is assumed that the width of the port is equal to the maximumopening of the exhaust port, and to construct the diagram it will firstbe required to uncover the travel of the valve, which is carried out, as shown inFig. 21, by drawing a circle of indefinite radius and marking on it pointsof cut-off, release, and compression. This can readily be completed, considering that thesepoints, if provided in terms of the stroke, as explained in Chapter III,might be discovered in terms of the angle turned by way of by the crank. Jointhe points of release and compression by the line A—B and via 0draw a diameter perpendicular to this line. It is then plain that theratio of valve travel to the offered width of port is equal to the ratio ofW—Y to X—Y and from this the trav

Note About Images

Please note that these pictures are extracted from scanned web page pictures that might have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not completely resemble the original operate.

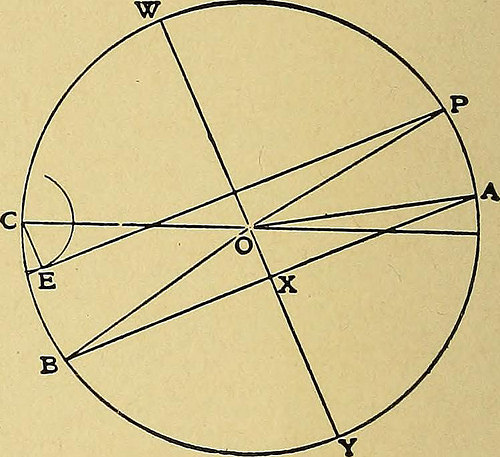

Image from page 9 of “The Parisian tailor system of dress cutting..” (1890)

Image by Internet Archive Book Photos

Identifier: parisiantailorsy00levi

Title: The Parisian tailor system of dress cutting..

Year: 1890 (1890s)

Authors: Levis, D. I. [from old catalog]

Subjects:

Publisher: [n.p.]

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Pictures From Book

Click here to view book on the internet to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Ahead of Image:

square make a dot on line 1 six inches under line 4.Make another 2 inches inside of this dot, and yet another four measuremore than Waist measure, employing back Waist figures, and draw lines12, 13, 14 and 15, as shown in reduce. TRACING FRONT. 1. Lay lining as for Back Trace line 11 from line 1 to 9 up line 9to 12, up 12 lo five, up five to 4, down line four, 26 and 1 down 24 and 15,19, 13, 18, 20, 14, 16, 17, 21 and 22. Get rid of draft, reduce out, allow seams except Neck and Arm Eye.Replace draft for Beneath Arm gore. Trace line 7 from 9 to eight upseam except Arm Eye. 9, 12, down 23 and 25, reduce out let TRACING OUT BACK. 1. Lay lining on a table double and tack drafting on the lining,First trace line four from line 10 to 7 up line 7 to 2, and line 2 to 8down line 8 to ten, down lines ten, 12 and 13, remove draft, reduce out,permitting seams except at Neck and Arm Eye. 2. Replace for side type Trace line four from six to 11 up lines 11, 6 and 9, down lines 14 and15, let seam except Arm Eye. Parisian Tailor Method of Dress Cutting

Text Appearing Right after Image:

DRAFTING FRONT. Lesson No. three. 1. Draw line 1 and 2 as shown in reduce. Make a dot on line two ac-cording to Neck measure, utilizing Front Neck figures. Line 3 is drawni~y2 inches below line 2. 2. With curvatures location the N point at dot on line two and neckmeasure on line 1, draw line 4, location the P point at exact same dot and 7inch mark in the same curve on line three, and draw line five to theShoulder measure. 3. Now make a dot *4 of the Arms Eye measure under the endof line five, and draw line six from line 1, square across this dot to thewidth of front. Line 7 is the Under Arm measure beneath line six andy2 in. a lot more than the width of front from 1. Draw line eight as shownin cut. Place the square corner of square at the junctions of line 6and eight and make a dot at Arms measure, making use of small Arms Eye fig-ure. Make a dot on line 7 in the identical manner, inside line eight. Drawline 9 as shown in cut. Now make a dot on line 9 y? inch belowline six, yet another three inches. Make a dot on line 1 four inches below line6. Make another on line 1 th

Note About Images

Please note that these images are extracted from scanned page pictures that could have been digitally enhanced for readability – coloration and look of these illustrations may not completely resemble the original work.

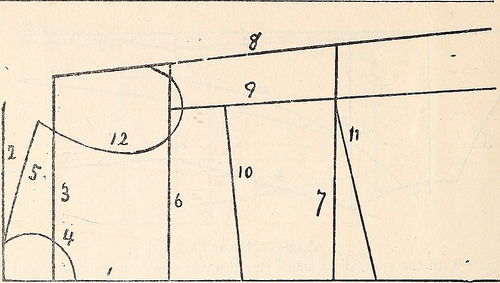

Image from web page 18 of “Merz’s practical cutting program for ladies’ jackets and cloaks ..” (1911)

Image by Web Archive Book Pictures

Identifier: merzspracticalcu00merz

Title: Merz’s sensible cutting method for ladies’ jackets and cloaks ..

Year: 1911 (1910s)

Authors: Merz, William. [from old catalog]

Subjects: Tailoring (Women’s) [from old catalog]

Publisher: [New York?] W. Merz

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Photos From Book

Click here to view book online to see this illustration in context in a browseable on the web version of this book.

Text Appearing Before Image:

perpendicidar line from A to 32. From 29to 31 is y^ back depth. Curve the line frnm 31 via K andA to S, which is % inch from 32. Draw the guide lines fromI through the center of C and D to establish T, and from Gto U parallel with ]>revious line. Divide the balance 3^4 inchesin 5 equal parts, which is -J^ inch every, and add a single on eachside of U, a single on each and every side of T, and the fifth -)4 inch on theside of S draw guide lines from B to the side of S from Cand D, from E and F to every side of T, and each side of U.Then draw the front center line from M to V parallel with theoutside line. From V to W is y% inch far more than from M to N.The nieasure from 22 to V is hip surplus four^^ inches on thisdraft and has to be cut out from W to Z. Draw guide linesfrom Q to Z and from N to V. Curve all lines as representedand the draft is prepared to be cut out. The length lines are ex-plained in styles. About the use ()f the cuntri)] measure, seeDiagrams X. and XL For Ladies Jackets and Cloaks. 17

Text Appearing Right after Image:

Diagram III. Merzs Practical Cutting Method Diagram IV.TIGHT^FITTING JACKET. TWO DARTS. All following drafts exactly where no special measures are givenare from the tahle of proportional measures of 36 bust. For two darts the front center line, ten to M and 11 to V,is J4 inch. Pivot at 25 and draw a circular line by means of L toestablish the height of the darts and put the darts, 43 and 44,/12 bust apart on each side of L. From M to N is % waistfrom N to O is V12 bust to be cut out from O to P is ^/^abust from P to O is the balance of the front waist surplus21 to M = two>4 inch on this draft. From V to W is J4 inchmore than from M to N from W to X ^ inch a lot more thanfrom N to O to be cut out from X to Y is 14 inch a lot more thanO to P from Y to Z is the balance of the hip surplus 22 to V= three inches on this draft. Then draw the guide lines from 9 to M from M to Vfrom the first dart point 43 to N from N to W from 43 to O from O to X and from the second dart point 44 to P fromP to Y from 44

Note About Images

Please note that these photos are extracted from scanned page pictures that might have been digitally enhanced for readability – coloration and appearance of these illustrations could not perfectly resemble the original function.

IMG00411

A couple of nice cnc milling firm photos I discovered:

IMG00411

Image by sdbrown

Dad and the central function of the clubhouse.

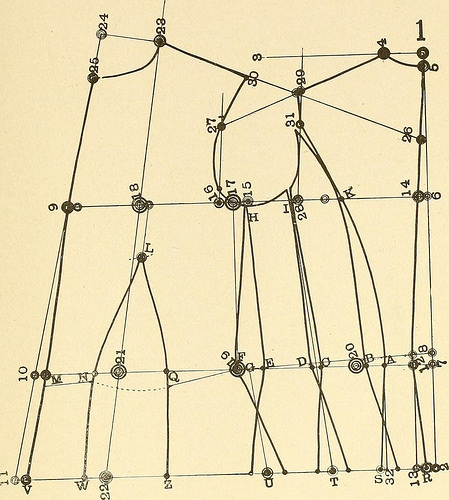

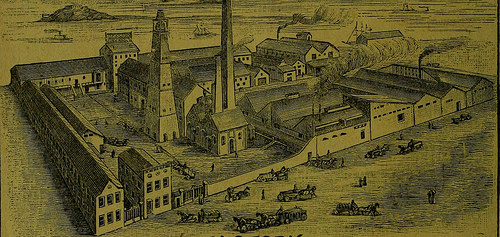

Image from page 9 of “Langley’s San Francisco directory for the year commencing ..” (1880)

Image by Internet Archive Book Pictures

Identifier: langleyssanfranc1894sanf

Title: Langley’s San Francisco directory for the year commencing ..

Year: 1880 (1880s)

Authors:

Subjects: Company enterprises Industries

Publisher: San Francisco : Francis, Valentine & Co.

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Ahead of Image:

Cltj Office, 509 ■ 511 MarM Street. Oie of Worb, 332 Baj areet, SAiy FRASfCISCO, CiL..

Text Appearing Soon after Image:

FACTORr ir.W HOPKINS CNC. MANUFACTrKERS OF WIRE of all Sorts. BARBED WIRE—Regularly L.icensed. PACIFIC WIRE NAIES, Greatest Steel. WIRE ROPE, Flat and Round. WIRE NETTIBfG. Galvanized After Slade. WIRE CLOTH, Ste<^l, Iron and Brass. Agents for the HALLIDIE WIRE ROPEWAY for the Economical Transportation of Ore and Other Material Over Mountainous and DiflB-Cult Roads. SElsTID IFOIS, ZDDESSCEailPTIVE O^T^XjOC3-UE. Our Wire Mills have a capacity of ten,000 tons of Wire, and as we draw our personal Wire from thebest Steel Wire Bods we guarantee top quality. Onr Barbed Fence Works are fully equipped to meet the demands on this Coast, and we usuallykeep a stock of 10,000 Spools on liaud. Trade Mark, Pacific. Onr Nail Operates have the most recent Improved nail- machines and we turn out 300 kegs day-to-day. TradeMark, Pacific. Tlie W^ire Rope Factory comprises the newest enhanced machinery, and we can refer to the variousCable Railways and Mining Organizations as to the quality of our Bope. Our Performs cover 2li acres c

Note About Pictures

Please note that these photos are extracted from scanned web page images that may possibly have been digitally enhanced for readability – coloration and look of these illustrations may possibly not completely resemble the original work.

Okuma's New VTM-2000YB Multitasking CNC Turning Center Gives Heavy …

Okuma's New VTM-2000YB Multitasking CNC Turning Center Offers Heavy …

At IMTS 2014, Okuma will introduce its new VTM-2000YB multitasking CNC turning center, which offers heavy-duty construction for big parts machining. The extreme rigidity and effective cutting capabilities of this machine make it ideal for machining …

Study much more on Robotics Tomorrow

The Dawn of the Sensible Factory

For instance, in CNC turning operations, a number of diverse machines are employed with an external controller, such as conveyors or robotic arms to move elements from machine to machine and align them under the guidance of industrial cameras before …

Read a lot more on Quality Magazine

1st-rate auto shop has each and every service for high-functionality and customization

Blackened steel stair with stainless treads

Image by Caliper Studio

Center stringer comfort stair connects two office floors in Starret Lehigh developing. Stringer and slab edge assemblies are blackened. Twenty 4 stainless steel treads are welded to the stringer type a continuous ribbon. 1 1/4" diameter handrail posts are continuous bent "C" shapes that wrap about treds and are welded to stringer. Stair will be delivered to site in one piece [24′ extended 3′ wide 3′ tall @ 2000lbs].

Design and style by Diller Scofidio + Renfro

Detailing, Fabrication and Installation by Caliper Studio. Caliper Studio engaged Eckersley O’Callaghan & partners for engineering services.

Initial-price auto shop has every service for higher-performance and customization

If you're looking for some wonderful solutions to customize and boost the overall performance of your car, verify out Misener Motorsports in Brantford, Ontario. Misener Motorsports specializes in auto maintenance, repairs, and high-performance demands. From precise …

Read more on Brant News

Behind the scenes with Dominic Wilcox making his "stained-glass driverless vehicle"

The painstaking procedure of generating the auto hasn't gone totally to program, Wilcox says, and he has had to improvise and adapt throughout. "I drew the shape of the vehicle and I put it onto a computer but till you really get your hands dirty, cutting this …

Study much more on Dezeen

Lastest Metal Grinding News

Samsung Introduces 2015 Samsung Zipel Asak M9000 with ‘Metal Ground’ Technology

Image by samsungtomorrow

Samsung Electronics has introduced its new premium Kimchi refrigerator 2015 Zipel Asak M9000 to the Korean industry. The new Zipel Asak M9000 comes with the Metal Ground technologies which virtually completely recreates the ideal underground conditions for storing Kimchi.

땅 속에 묻은 김치처럼 아삭하고 맛있게~" 땅 속 김장독을 그대로 구현한 ‘2015년형 삼성 지펠아삭 M9000’ 출시

국내 김치냉장고 시장을 선도해온 삼성전자가 17일 ‘메탈그라운드’ 기술을 앞세우며 프리미엄 김치냉장고 ‘2015년형 지펠아삭 M9000’ 신제품을 출시한다. 삼성전자 ‘2015년형 지펠아삭 M9000’은 우리 옛 조상들이 김장독을 땅에 묻어 정온을 유지해 김치의 맛을 살린 지혜처럼 냉기 전달과 보존 능력이 뛰어난 메탈 소재를 적용해 땅 속 저장 환경을 완벽에 가깝게 구현한 ‘메탈그라운드’를 채용했다.

[삼성투모로우 블로그 관련 포스팅]

Samsung Electronics announced on 17th that the company has sealed a Olympic Partnership deal with the IOC(International Olympics Committee) at Nanjing, China to expand its sponsorship period for the Olympic Games to the year of 2020.

삼성전자, IOC와 2020년까지 올림픽 후원 계약

삼성전자가 2018년 평창 동계올림픽과 2020년 도쿄 올림픽을 공식 후원한다. 삼성전자는 17일(현지시간) 중국 난징에서 국제올림픽위원회(IOC)와 2020년까지 올림픽 공식 후원을 연장하는 계약을 체결했다고 밝혔다.

[삼성투모로우 블로그 관련 포스팅]

samsungtomorrow.com/JOS2o

Machine Tool Company Gears Up

Numerous have been collecting cost sheets and quotes in a sign a recent downturn might be grinding to an end. "I'd like to get one thing going by the finish of the year," mentioned James Martin, owner of Martin Sheet Metal Inc. in Cleveland, who was hunting for robotic …

Study a lot more on Wall Street Journal

Cheap, Scratch-Resistant Displays

Glass touch-screen displays are simply cracked and scratched, creating them a weak point in nowadays's ubiquitous mobile devices. Sapphire—second only to diamond in hardness—could make such harm a thing of the previous. Sapphire is already used on a handful of …

Read a lot more on MIT Technology Evaluation

'Chronicle' pressroom takes pride in every run

John and I would arrive early in the morning, long after Joe and Stan had completed the tough function of making, then hanging, the metal plates on our Goss offset printing press. They would crank up the machine, set the color, get the pages in register and …

Read more on The Augusta Chronicle

Lastest Cnc Grinding Machine News

Hardinge to Obtain Voumard

Hardinge applies its engineering design and style and manufacturing knowledge in high efficiency machining centers, higher-finish cylindrical and jig grinding machines, SUPER-PRECISION® and precision CNC lathes and technologically advanced workholding …

Read far more on CNNMoney

2015 Machine Tool Consumption Forecast – Up 37 %

Additionally, next year could see the U.S. become the number one consumer of CNC machine tools for the initial time since 2000. While the general economy remains mired in slow growth, the four main top indicators for … the most preferred machine …

Read much more on Modern day Machine Shop (weblog)

Streamline Supply Chain With One-Stop Metal Fabrication

… capabilities through a series of strategic corporate acquisitions over decades. Nowadays, Summit Steel offers a full-range of solutions from 2D and 3D laser cutting, CNC turning/milling, Swiss machining, and centerless grinding/polishing to bending …

Read a lot more on Manufacturing.net

Centerless Grinder Resists Deflection

The grinding machine is constructed on the firm's eight"-thick (203-mm-thick) Starrett surface-plate-quality granite with a .002" (five-micron) flatness specification for enhanced rigidity and thermal properties. Regulating wheel spindles are servo-driven …

Read far more on Contemporary Machine Shop

Additive Manufacturing Professional EOS Joins Commonwealth Center for Advanced …

Additive Manufacturing Expert EOS Joins Commonwealth Center for Advanced …

In the case of a close to-net DMLS portion, a milling or CNC cutting procedure might be far more suitable. And the resulting production line may be … The 62,000 square-foot facility at the Center's Prince George County property includes computational software program and …

Read far more on ENGINEERING.com

Rockwell and Fanuc announce international collaboration

Robomachines are Fanuc's robotic machining centres, which contain injection moulding, vertical milling and EDM (electrical discharge machining) systems. The principal initial influence of the new collaboration is expected be in the automotive industry, exactly where …

Read a lot more on Drives & Controls

IMTS 2014 Conference: Re-evaluating the EDM Approach

Till not too long ago, several companies of titanium components have deemed electrical discharge machining (EDM), either fully off limits, or to be employed as a main process coupled with a secondary operation. A lot of instances, the secondary operation is …

Read more on Today’s Power Solutions

CNC Software participates in 3rd annual MFG Day

Tolland, Connecticut – CNC Application, Inc., creators of Mastercam CAD/CAM software, will host an open residence at its manufacturing facility situated at 671 Old Post Road, Tolland, Conn. to celebrate Manufacturing Day. The open house will be held on Friday, …

Read a lot more on Aerospace Manufacturing and Design and style