The testing plan tells what number of or potentially how frequently to investigate measurements. A review plan determines what measurements to assess and what estimating instruments and procedures to use during examination. Much the same as procedure plans and examining plans, investigation plans can be totally different from organization to organization, however they all achieve a similar errand. Formal review plans are commonly utilized in high precision CNC machining parts or other creation conditions where enormous quantities of similar parts are machined or when complex shapes are delivered.

Determination of Critical Dimensions

The main assignment while making a review plan is determination of basic measurements for cnc machining suppliers. The meaning of a basic measurement is not entirely clear, however regularly they are measurements with the littlest or most impenetrable tolerances.

Another highlight consider is whether various activities or numerous machines are utilized to machine a section. Assuming this is the case, connections between measurements delivered by various activities might be called basic on account of varieties in how the part is made sure about during those tasks. A basic measurement may likewise be one that adjusts mating parts. On the off chance that diverse cutting instruments perform cnc machining manufacturing, the first and additionally last measurement delivered by each apparatus may likewise be viewed as basic to be certain that each device is performing alright to meet print resistances.

Determination of Measuring Tools and Procedures

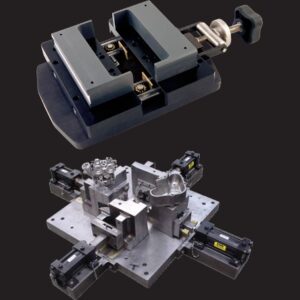

When choices are made on basic measurements, estimating instruments and methodology must be chosen. Apparatus decision and investigation techniques rely upon the resilience of the measurement being examined. Think about a direct measurement with a resilience or admissible variety of 0.0001″. Positively a standard would never gauge precisely enough to assess this resilience. A vernier or dial caliper would not be reasonable either since their scales just read to 0.001″. Indeed, even a micrometer with a vernier scale would be faulty. Despite the fact that its scale peruses to 0.0001″, the worry would be that the measurement probably won’t be estimated reliably each time. On account of a 0.0001 ” resilience, a test marker, gage squares, and surface plate may be the most ideal decision. Then again, if a resilience were 1/16″, a standard would be adequate and utilization of a dial test pointer, gage squares, and surface plate would require considerably more time and exertion than required.

That would be wasteful, superfluous, and excessively expensive. The report advises what number of parts to investigate and when, just as what measurements to examine and the apparatuses and techniques to play out the examination. It likewise gives space to the investigator’s initials and to record estimations, dates, and times. The subgroup synopsis segments demonstrating normal and range will be examined quickly.

Statistical Process Control (SPC)

Statistical procedure control (SPC) is an advanced technique for following variety in sizes of machined parts. SPC utilizes the measurements determined in an investigation plan from the example parts delineated in an examining plan. SPC plots information on two sorts of outlines to examine patterns to a limited extent variety. They are called control outlines. This data assists with foreseeing the consistency of an activity and aides changes in accordance with the activity before it begins to create parts outside of resistances.

SPC programming can naturally make these diagrams by contributing estimation information. The information port on some estimating devices (normally computerized models) can be associated with a unique link to a PC running SPC programming. At that point estimations can be sent to the product and be consequently prepared for making of these outlines.

This article is from www.tinymachining.com