Some cool cylindrical grinding solutions pictures:

Image from web page 129 of “Railway and locomotive engineering : a practical journal of railway motive energy and rolling stock” (1901)

Image by World wide web Archive Book Images

Identifier: railwaylocomotiv36newy

Title: Railway and locomotive engineering : a practical journal of railway motive energy and rolling stock

Year: 1901 (1900s)

Authors:

Subjects: Railroads Locomotives

Publisher: New York : A. Sinclair Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Photos From Book

Click here to view book online to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Before Image:

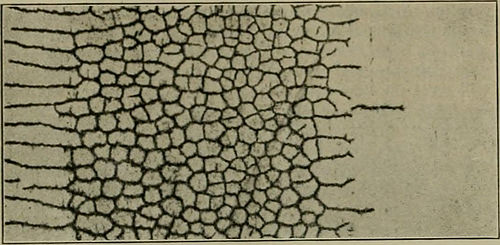

by the lirinell strategy. Underthese conditions, when the imprcNsicm is examined underthe microscoi>e, tine cracks arc often observed, buteven when the metal appears tu have been left i)erfectly in-tact, the cracks can k develoi>ed as stated above, by at-tacking it with acid when radial cracks will Im formedwhich are completely distinct and whicli typically assume theform of a re,i,ular star radiating from the sides of theimpression. The length of these cracks indicates the ex-tent of the cold rolling impact developed by the ball aroundthe inii)riiit itself. This e.ixrimeut can )c very readilymade on tools that have been quickly temjjered, or uixjnthe ix)ints of shells intended to burst. In steels of average qualitv possessing a tensile strength offrom 90,000 to 100,000 lbs. per sq. in., the total sujx^r-ficial cold rolling is a lot a lot more difliailt to get. It isthen imix)ssible to produce this result by grinding. Inorder to rci>r(iduce the ])lienomenon ol)served in rails, they

Text Appearing After Image:

Surface of 82 lb. Rail Broken in Service. The Fine Cracks WereClearly Visible to the Eye on the Polished Surface. Enlargedto Twice the Natural Size had recourse to an analogous method initially pointedout by EHiguet, who referred to as focus to the similarity ofthe perform carried out by the wheels of a train and by the rollsof a mill. The test is ea.sy to make if we make use of the samerolls on steel of semi-challenging (|uality as are employed in themanufacture of rails. Now, on a huge quantity of thesecylinders there has been observed, soon after they have been inservice for a particular length of time, that they developidentically the exact same type of fine cracks as are pro-duced in rails. And the identical i)hennmena have l)eeiiobsened on the cylindrical trunnions of rolls for steel. A case may be cited which appears, at first sight to bequite diverse from those referred to aliove it is that ofthe erosion of the bore of cannon, which has l)een thesubject of quite a few investigations by Professors Howeand Fay. By an examinati

Note About Photos

Please note that these photos are extracted from scanned web page pictures that may possibly have been digitally enhanced for readability – coloration and appearance of these illustrations may not completely resemble the original operate.

Image from web page 1275 of “Electric railway journal” (1908)

Image by Web Archive Book Photos

Identifier: electricrailway501917newy

Title: Electric railway journal

Year: 1908 (1900s)

Authors:

Subjects: Electric railroads

Publisher: [New York] McGraw Hill Pub. Co

Contributing Library: Smithsonian Libraries

Digitizing Sponsor: Smithsonian Libraries

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click here to view book on-line to see this illustration in context in a browseable on-line version of this book.

Text Appearing Ahead of Image:

Bemis Vehicle Truck Co., Springfield, Mass. July 7, 1917] ELECTRIC RAILWAY JOURNAL 67

Text Appearing Following Image:

GRIFFIN F. C. S. WHEELS ARE ECONOMICAL Several electric railways safe the greatest amount of mileage by the use of apit car wheel grinder. The vehicles are run onto the grinder, and in twenty to fortyminutes the wheels are ground genuinely cylindrical, eliminating service defects andmaking a new wearing surface of the proper taper. A wheel grinder eliminatesthe expense of removing wheels from the trucks, and re-applying. The use of Chilled Iron Wheels does not involve the price of an expensivewheel lathe. The wear on rails due to flange friction is at a minimum. Twenty to twenty-5 per cent, in the loss of metal of brake footwear is saved. GRIFFIN WHEEL Company McCormick Creating, Chicago, 111. FOUNDRIES Chicago Detroit Boston Denver St. Paul Tacoma Kansas City Los Angeles 68 ELECTRIC RAILWAY JOURNAL [July 7, 1917 The new high speed interurban carsrecently placed in service by theJamestown, Westfield & North-western Railroad are fitted withStandard No. 1062 rolled steelwheels mounted on Standar

Note About Photos

Please note that these photos are extracted from scanned web page pictures that might have been digitally enhanced for readability – coloration and look of these illustrations may possibly not perfectly resemble the original work.

Image from page 115 of “Railway mechanical engineer” (1916)

Image by Web Archive Book Pictures

Identifier: railwaymechanica93newy

Title: Railway mechanical engineer

Year: 1916 (1910s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad cars

Publisher: New York, N.Y. : Simmons-Boardman Pub. Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Photos From Book

Click here to view book on-line to see this illustration in context in a browseable on the web version of this book.

Text Appearing Just before Image:

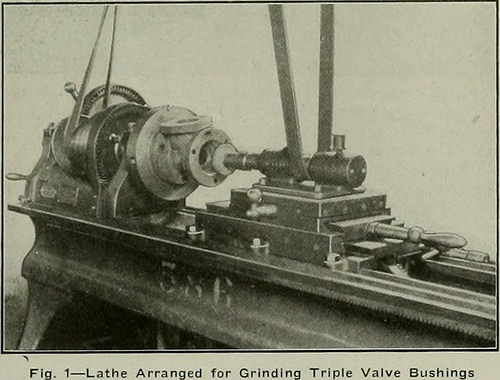

It is equally applicable to the front, finish or sidesof tile locomotive. One more intriguing security measure adopted at this shopis that, as shown in Fig. eight, of setting the tloor hose connec-tions at an angle so that they do not blow straight in the faceof the operator when connections are being produced. Fig. 9 shows a substantial safeguard for a huge lye pit.This has, in addition to the two-higher pipe rail an end gatewhich swings open to allow tlie dipping vehicles to be run inand out with the material to be washed. Along every single sidethe space beneath the reduce rail is enclosed by sheet metal asindicated in the illustration. AIR BRAKE DEVICES AT BRAINERD SHOPS The Northern Pacific does a huge amount of air brakerepairing at the Brainerd, Minn., shops. In order to expeditethe function, numerous specific devices have been developed, afew of whicli are described beneath. One of the most usefultools in the air brake division is the machine for grind-ing the bushings of triple valves shown in Fig. 1, which was

Text Appearing Soon after Image:

Lathe Arranged for Grinding Triple Valve Bushings produced from an old brass lathe. In ordinary service thepistons of triple valves move principally among service andrelease positions and this causes the ring to put on the bush-ing through a modest portion of its length. When triple valvesare repaired at Brainerd shops the bushings are ground onthis machine to make them truly cylindrical. The physique ofthe valve is attached to a removaljle face plate which can becentered by implies of screws. The grinding wheel is mountedon an extended spindle, carried on the cross slide and drivenfrom an overhead counter shaft. By centering the bushing,setting the wheel to take a light reduce, and moving it back andforth although the body is gradually revolved, the bushing can bemade true and smooth without removing any more metal thanis necessary. By altering face plates the machine can beadapted to any variety of latlie. The uneven put on of bushingsis the frequent trigger of irregular action in triple valves anda machine f

Note About Images

Please note that these photos are extracted from scanned web page images that may have been digitally enhanced for readability – coloration and look of these illustrations could not perfectly resemble the original work.