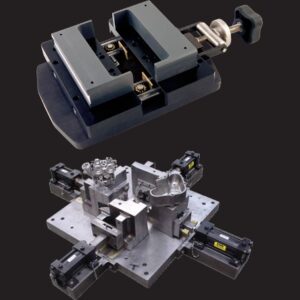

Some cool surface grinding manufacturer images:

11_all sugar imports thereafter

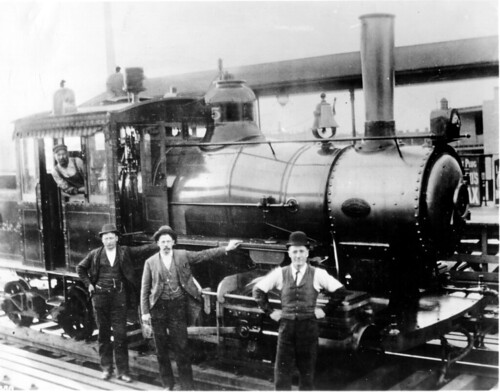

Image by Jim Surkamp

Income Wizard R. D. Shepherd and His Fabled Building – McMurran Hall, Shepherdstown, WV by Jim Surkamp

civilwarscholars.com/?p=13106 7907 words.

Made achievable with the generous, community-minded help of American Public University, offering a top quality, on the internet education. The interpretations of posts in civilwarscholars.com do not in any way reflect the modern day-day policies of the University. More at apus.edu

Patriarch R. D. Shepherd’s Homecoming 1859

1_About how a young boy from Shepherdstown

About how a young boy from Shepherdstown constructed a enormous fortune by way of work, smarts and an act of his own heroism for one more then, turns about and provides much of it back as McMurran Hall, an Almshouse in New Orleans and other gifts.

two_R. D. Shepherd had a strict, flinty way

R. D. Shepherd had a strict, flinty way, but on paper and in the world at massive did his massive generosities stand tall, pervade the landscape and enrich the hearts of humanity.

3_Seventy-5-year-old Rezin

Seventy-5-year-old Rezin Davis Shepherd, described by the New Orleans Picayune as having “the largest and most productive estate which has ever been held by a single particular person in this city and State” – began the construction Thursday, October 6th, 1859 of a present to his home town, this time proper on lot no. 1 in Shepherdstown, the very lot exactly where he was born in August 1, 1784.

4_Who knew that in ten fleeting day

Who knew that in ten fleeting days – October 16th – history would be blown off its hinges by the John Brown raiders’ attack fifteen miles away at Harpers Ferry, the match that lit the simmering fever of division among

five_North and South more than slavery

North and South over slavery and claimed rights to secede from the Union. The tempest raged back and forth over the county and the town for 1300 hundred days of pitiless strife and war before settling back into getting a barren, alien landscape.

6_RD’s creating

RD’s (“RD” henceforth for “Rezin Davis Shepherd”) building – gorgeous as were all his buildings remains a Greek Revival style, with a two-story-portico and Corinthian flourishes. But in the 1860s, it would bear witness to all that was rent asunder and itself narrowly avoid destruction, unlike a much less lucky altruistic juggernaut project of Shepherd’s in New Orleans – the palatial Almshouse. But this, RD’s Town Hall, first named, would sooner or later reside a “long, happy life” very first as the County Court, then into its present-day majesty as the signature constructing of Shepherd University.

Increasing Up – RD Learns the Trade:

7_When he was just nine years old

8_placed him in the shop and counting house

When he was just nine years old, RD’s father, Abraham, placed him in the store and counting home in Baltimore of William Taylor,

9_an ambitious importer and ship-owner

an ambitious importer and ship-owner. RD’s incredible gifts surfaced when he – just eighteen – was sent to New Orleans to assure a great return on a large shipment of British goods his firm had bought for New Orleans’ customers. Then his 1st large “killing” was with one more fresh-faced, difficult-driving Taylor colleague, James McDonough. Wrote the Picayune: In October, 1803, it was nicely recognized throughout the nation that Louisiana had been bought by the United States. Mr. Taylor was the only merchant who seemed to comprehend the profit from one particular consequence of the this great political occasion.

ten_in becoming a state

11_all sugar imports thereafter

12_cornered 1800 of those hogsheads

The firm realized that in becoming a state, a duty of two.5 cents would be added to the value of all sugar imports thereafter. So Shepherd and McDonough – when all the sugar created in the state was between 2100-2200 hogsheads – cornered 1800 of these hogsheads, giving young RD “a handsome capital for a young man to start off in mercantile life.” He soon designed a new firm shared with Taylor, then in time through age and retirement became RD’s alone.

13_Coming into his personal

Coming into his personal, he married Lucy Taylor Gorham of Barnstable, Massachusetts in 1808, who was “a niece and adopted daughter” of Taylor. On August 22nd, 1809, their only kid, Ellen Shepherd, was born in Louisiana. (Lucy would die in 1814).

14_the penchant of RD

It was at this juncture the penchant of RD for standard, publicity-averse benefactions took root, in the moment of his willed defiance against a direct military order to work, alternatively, to save 1 specific wounded man, left for dead in war, a man who himself would live on to grow to be the epitome of the proverbial Good Man, albeit

15_His name was Judah Touro

extraordinarily wealthy. His name was Judah Touro, a prime-hatted, but humble Jewish businessman who believed in respect for all religions and day-to-day applications of the code of excellent functions. He was beloved throughout his circles and area as “the Israelite with out guile.”

Wrote Author Colyar:

16_Wrote Author Colyar

17_carrying ammunition on the battle field

While carrying ammunition on the battle field Jan. 1, 1815 Mr. Touro was struck by a 12-pound shot which tore

18_12-pound shot

19_a large mass of flesh from the thigh

a large mass of flesh from the thigh and prostrated him among the dead and dying. Mr. Rezin Shepherd, was carrying a unique order from Commodore Patterson across the river to the main army. On reaching the bank he met a pal, who told him his buddy Touro was dead. Inquiring where he was, Shepherd was informed that he had been taken to

20_Jackson’s headquarters

an old constructing in the rear of Jackson’s headquarters. Forgetting his orders, Mr. Shepherd went immediately to the spot and discovered he was not dead, but, as the surgeon stated, in a dying situation. Disregarding what the surgeon mentioned, Shepherd got a cart, put him in it, administered stimulants, and took Touro to his personal residence. He then procured nurses, and by the closest consideration, Mr. Touro’s life was saved. Mr. Shepherd returned late in the day,

21_Commodore Patterson in a bad humor

having performed his mission, to find Commodore Patterson in a poor humor, and, speaking severely to him, the latter mentioned: “Commodore, you can hang or shoot me, and it will be all proper, but my greatest pal needed my assistance, and practically nothing on earth could have induced me to neglect him.”

RD’s organizations continued to develop exponentially and his brother, James Hervey Shepherd, was summoned from Shepherdstown to assist.

22_Shepherd, was summoned from Shepherdstown to assist.

1817-1837 – RD travels to Europe, settles in Boston doting on his daughter’s education.

23_1822 – RD maintained his companies

24_at 5 Pearl Street and nearby 28 Indian Wharf property.

1822 – RD maintained his businesses and shipping concerns at 5 Pearl Street and nearby 28 Indian Wharf residence.

25_her portrait painted by Thomas Sully

26_Gilbert Stuart is commissioned to paint his own portrait

He has her portrait painted by Thomas Sully in 1831, a couple of years following Gilbert Stuart is commissioned to paint his personal portrait. (Stuart died in 1828).

1829, April 20 – Ellen Shepherd marries Gorham Brooks of Medford, Massachusetts.

1834 – RD commissions Samuel Fuller to create the 480-ton merchant ship in Medford, named following his daughter, the “Ellen Brooks.”

27_James Hervey Shepherd dies

1837 – James Hervey Shepherd dies. RD returns to run organizations in New Orleans.

1837, July 23 – Ellen (Shepherd) Brooks and her husband, generally in Boston or Medford, temporarily reside in Baltimore.

28_nephew, Henry Shepherd Jr.

1837-1865 – RD’s nephew, Henry Shepherd Jr., who was brought up in his uncle’s counting area, steadily assumes the role as RD’s agent in New Orleans.

29_painting of the ship the “Ellen Brooks” is completed

1839 – RD’s commissioned painting of the ship the “Ellen Brooks” is completed, attributed to Samuel Walters (British, 1811-1882), called “Ellen Brooks, Off Holyhead, Homeward Bound.”

1841 – RD buys 468 acres of land and begins developing Wild Goose Farm, but not however living there complete-time he also pays for most of the remodeling of the original Trinity Episcopal Church in Shepherdstown.

1842, June – RD signs a petition to Congress along with many other planters and sugar companies in the state of Louisiana that asks for an improve in the duties on imported sugar.

1849 – RD locations responsibilities on his eighteen-year-old nephew, Henry Shepherd Jr., who would grow to be his agent in New Orleans via the Civil War, enabling RD to return much more permanently to his Wild Goose Farm.

30_Wild Goose Farm

31_the 1850 Census shows

32_1850 and 1860 Census slave schedules

1850 – In Shepherdstown & Wild Goose Farm the 1850 Census shows 66-year-old RD with a period worth of ,000, living only with workmen: 26-year-old German-born master stonemason Conrad Smith and an overseer. Although a single account states Touro stipulated that RD cost-free his enslaved persons, RD is shown to having owned many persons, enumerated in each the 1850 and 1860 Census slave schedules.

1854, January 6th – Touro’s Will makes Rezin Davis Shepherd residuary legatee of the estate and executor 5,000 is willed to particular recipients. A sum iof ,000 is set aside for a palatial almshouse, with the added stipulation to RD that more sums, if required, need to be utilized to complete this priority project.

Judah Touro produced out his will January six, 1854 a few days just before his death that stated:

33_my dear, old, and devoted friend, Rezin Davis Shepherd

34_I hereby appoint and institute him

As regards my other designated executor, say my dear, old, and devoted buddy, Rezin Davis Shepherd, to whom, below Divine Providence, I am tremendously indebted for the preservation of my life when I was wounded on the 1st of January, 1815, I hereby appoint and institute him, the mentioned Rezin Davis Shepherd, soon after payment of my specific legacies, and the debts of my succession, the universal legatee of the rest and residue of my estates, movable and immovable.

35_funded remodeling of the Trinity

RD continued his projects each in New Orleans and Shepherdstown. He had already funded remodeling of the Trinity

36_planned a clock and bell to its original church

Episcopal Church. He planned a clock and bell to its original church then right after some legal squabbling – the clock – to everyone’s assent – was reassigned to be inserted in to the new government developing.

The Shepherd Household is Scattered By War:

37_The war hit the family challenging

The war hit the family members hard. Most of the young guys enlisted in Virginia units. RD had to recalibrate his enterprise strategies. Wrote the Richmond Daily Dispatch: June 8, 1861:

The New Orleans Delta states that R. D. Shepherd, Esq., who is now at an sophisticated time of life, living on his lovely farm close to Shepherdstown, Virginia, has directed his agent in New Orleans to pay more than to the treasurer of the Confederate States a massive sum of income, which includes, it is said, his complete annual earnings from rents in that city — the largest income enjoyed by any home holder — to be applied to the defence of the rights and the help of the independence of the South.

38_spring of 1862 when Federal General Banks

In the spring of 1862 when Federal General Banks with his army entered into Jefferson County, RD took refuge in Boston with his daughter.

39_As the war progressed

As the war progressed, its maw of destruction came closer to Shepherdstown’s nearly full developing. 130,000 troops moved in the area in September, 1862 for the bloody Maryland Campaign, just across the Potomac river. Wounded from the nearby battles poured into Shepherdstown, placing the unfinished Town Hall into service as an outdoor hospital.

Wrote Mary Bedinger Mitchell:

40_The unfinished Town Hall had stood in naked ugliness

The unfinished Town Hall had stood in naked ugliness for numerous a lengthy day. Somebody threw a few rough boards across the beams, placed piles of straw over them, laid down single planks to walk upon, and lo, it was a hospital at once.

There have been six churches and they were all complete, the barn-like spot identified as the Drill Room, all the private houses soon after their capacity, the shops and empty buildings, the school-homes – each and every inch of space and yet the cry was for more room.

We went about our work with pale faces and trembling hands, however attempting to appear composed for the sake of our individuals, who had been a lot excited. We could hear the incessant explosions of artillery, the shrieking whistles of the shells, and the sharper, deadlier more thrilling roll of musketry while every now and then the echo of some charging cheer would come, borne by the wind, and as the human voice would pierce that demoniacal clangor we would catch out breath and listen, and try not to sob, and turn back to the forlorn hospitals, to the suffering at our feet and prior to our eyes although imagination fainted at the believed of these other scenes hidden from us beyond the Potomac.

Had Federal Common George McClellan crossed the Potomac and pursued Common Lee’s scattered and mauled army, as historians have a lot criticized him considering that for not undertaking, Shepherdstown would have most likely suffered greater harm, but, as it was, shells landed in the yards of the Lees and Morgans and one particular or two even hit Shepherd’s new Town Hall, but were of small consequence.

Property Losses in New Orleans:

41_RD’s fine residence at 18 Bourbon Street

42_18 Bourbon Street in New Orleans

A lot more invasive, improvised use was becoming made of RD’s fine residence at 18 Bourbon Street in New Orleans, causing his nephew to formally appeal to the Federal powers-that-be in early 1864. He wrote:

43_From Brig. Common James Bowen

January 29, 1864

From Brig. Common James Bowen

Provost Marshal General

Division of the Gulf.

Sir:

The undersigned acting as the duly authorized agent and attorney in reality of Rezin Davis Shepherd, formerly the State of Virginia, but for far more than eight months past residing with his daughter Mrs. Gorham Brooks in the city of Boston and State of Massachusetts, respectfully represents: That the mentioned Shepherd is a loyal citizen of the United States and the accurate and lawful owner of the Brick Dwelling No. 18 Bourbon Street between Canal and Custom Property Streets in the City of New Orleans and also of all the furnishings and contents thereof: that in the month of June, 1862 Col. Stafford with out show of authority, placed in possession of said property and contents, a man by the name of Horton or Houghton, who has ever because occupied and now occupied and utilizes the exact same as a Boarding Residence, and who by no means has paid any rent or compensation there and continually refused to do so.

Under the situations, the undersigned respectfully appeals to you, General, for relief, and asks that the matter be referred to Capt. Edward Page and Thomas Tileston, or other of them for investigation and that the aforesaid premises and contents be restored to the possession of the owner without having delay Henry Shepherd Jr.

Like The Town Hall, the massive, magnificent Almshouse in New Orleans remained unfinished, to be hit by a worse fate. Shepherd was charged by Touro’s will to initial place ,00 toward its building, then be ready to put far more cash into its building- which includes even some of Shepherd’s personal funds – as recipient of Touro’s residue.

44_occupied by detachments of the 2nd Maine Cavalry

45_The fire started

46_Baked beans fired the developing

On September 1, 1865, at a time the Almshouse in New Orleans – still with an unfinished, floorless prime floor – was occupied by detachments of the 2nd Maine Cavalry and Firm K, First Louisiana Cavalry. A baking oven was in heavy use at 1 finish of the creating so that heat would be carried by way of a fissure in a ventilation program close by. The fire began in the rafters above the third floor. It was night-time with a higher wind and no flooring however laid for the third floor in that wing. Coals dripping from the fire then ignited tar on the reduced walls. “Baked beans fired the building” mentioned 1 from the 2nd Maine Cavalry. The developing was uninsured. Just a couple of months later R. D. Shepherd died of typhoid fever, November ten, 1865, no longer the executor of the estate, leaving no philanthropist to support make up the loss.

Wrote the editors of the Occasions-Picayune in a lengthy obituary:

In his native village he erected a splendid creating, designed for a town hall, also a massive academy, with gorgeous grounds and a walk. He also deposited with the Mayor annually a large sum to acquire fuel and provisions for the poor. He also erected the biggest and most costly church in Jefferson County. Numerous other acts of public and private benevolence had been performed by him in his quiet, furtive manner.

With war ended and when he was still healthy, RD had urged that his Town Hall turn into the County Court given that the Charlestown courthouse was a battle-scarred ruin, especially from a shelling it took in the fall of 1863.

A Visitor Contemplates Charlestown’s Ruined Courthouse in mid-1865:

47_the court-house, where that mockery of justice was performed, was a ruin

48_4 massive white brick pillars, still standing, supported a riddled roof

A short walk up into the centre of the town took us to the scene of John Brown’s trial. It was a consolation to see that the jail had been laid in ashes, and that the court-property, exactly where that mockery of justice was performed, was a ruin abandoned to rats and toads. 4 massive white brick pillars, nonetheless standing, supported a riddled roof, by means of which God’s blue sky and gracious sunshine smiled. The primary portion of the constructing had been literally torn to pieces. In the floor-less hall of justice rank weeds had been developing.

49_Names of Union soldiers have been scrawled along the walls

Names of Union soldiers had been scrawled along the walls. No torch had been applied to the wood-perform, but the operate of destruction had been performed by the hands of hilarious soldier-boys ripping up floors and pulling down laths and joists to the tune of “John Brown,” the swelling melody of the song, and the accompaniment of crashing partitions, reminding the citizens, who believed to have destroyed the old hero, that his soul was marching on. It was also a consolation to know that the court-property and jail would most likely in no way be rebuilt, the county-seat obtaining been removed from Charlestown to Shepherdstown — “forever,” say the resolute loyal citizens of Jefferson County, who rose to vote it back once more.

50_either buried in Elmwood Cemetery or the Shepherd Burial Ground

The Shepherd boys who enlisted in Virginia organizations every single – more than time – came home and had been either buried in Elmwood Cemetery or the Shepherd Burial Ground – or lived.

51_Clarence Edward Shepherd

Clarence Edward Shepherd became a teacher in Maryland.

Whilst RD’s nephew and agent, Henry Shepherd Jr. was in New Orleans in the course of the war, minding the loved ones interests, 3 of his brothers had been at war. The eldest Rezin Davis, his older brother who had a young family

52_eldest Rezin Davis, his older brother who had a young loved ones

considering that 1858, died of illness November two, 1862 at his “river cottage” soon after imprisonment in the Old Capitol Prison for getting an associate of Confederate spy, Redmond Burke. He left his widow, Elizabeth Boteler Stockton Shepherd, two kids (Fannie and Alexandria) and a third (David) on the way. Possibly very first buried on his farm, Rezin Shepherd (a nephew of the patriarch) was reburied after peace came in the new Elmwood Cemetery. His internet site was joined by all his family as time unspooled.

53_twenty-5 year-old Abraham

Henry Jr.’s next brother, twenty-five year-old Abraham, enlisted Could 22nd, 1861, would move more than to Co. F. of the 17th Virginia Cavalry, get wounded at the third battle of Winchester in September 19, 1864, and turn into a prisoner of war. But he survived the war and died a lot of years later in 1907.

54_Henry Jr.’s younger brother, James Touro (Truro) Shepherd

Henry Jr.’s younger brother, James Touro (Truro) Shepherd, enlisted as a Private Might 1st, 1861 in the 2nd Virginia Infantry. Like several, the rigors of marching below Gen. Stonewall Jackson proved an impetus to transfer out into a Cavalry regiment, and he joined Co. B of Gen. Stuart’s Horse Artillery below John Pelham, with a promotion to very first lieutenant. His service record ends abruptly in the spring of 1862. The Shepherdstown Register in September, 1865 reported him obtaining died in “Richmond City” in March, 1862. His marker dates his death as August 13, 1862, which may be the date of his re-internment into the household burial ground.

Two sons of James H. and his wife, Florence Hamtramck Shepherd have been buried a few feet apart in the loved ones burial ground on Shepherdstown’s New Street adjacent to the Episcopal rectory. Robert F. Shepherd, who joined Co. H, 2nd Va. Infantry, died Could 4, 1862 of pneumonia.

55_Robert F. Shepherd, who joined Co. H, 2nd Va. Infantry

56_Alexander H. Shepherd

Alexander H. Shepherd, who enlisted when he was about twenty-eight April four, 1861 in Co. H of the 2nd Virginia Infantry he died of typhoid fever at Camp Harman close to Fairfax Courthouse September 25-26, 1861.

57_Rezin Davis Shepherd was buried there also

Rezin Davis Shepherd was buried there as well, in his personal time.

He left all his fortune to his daughter, who, considering that 1855, had been a widow.

Wrote the Shepherdstown Register: A Large Estate – the late Rezin D. Shepherd left an estate valued at about ,500,000 all of which goes to his daughter, Mrs. Brooks of Boston. He was born in 1784 (on the lot where the court residence would be constructed). In 1809 he went to New Orleans and engaged in the commission business until 1849 and was the executor of the estate of the late Judah Touro. Mr. Shepherd was formerly a merchant in this city, residing on High Street. He accumulated a extremely large home in New Orleans and was reputed to be one particular of the wealthiest males of that city. Upon the breaking out of the rebellion, he returned to Boston and resided for a short time with his daughter and sole heir, Mrs. Gorham Brooks, widow of a son of the late Peter C. Brooks. His estate on High Street was formerly, we think the house of Samuel Dexter.

The Massachusetts Historical Society nowadays displays a cannon donated by the household and acquired by RD – a smaller sized version of the a single that so severely wounded RD’s friend, Judah Touro.

The visiting journalist Trowbridge was established incorrect – the county seat DID go back to the Charlestown Courthouse. Wrote the editors of the Charlestown-primarily based newspaper, The Spirit of Jefferson, in 1894:

58_The Regular College constructing, formerly the town hall

The Typical College developing, formerly the town hall, on Major Street, is a handsome structure, the present of 1 of the Shepherd family members, Rezin D. from which the town takes its name. You will remember that it was used as a court residence considering that the war and the courts of Jefferson county had been held there, one particular Judge Hall sitting on the bench. A political rape was perpetuated on Charlestown, the party in power, fitly termed radicals, thought they had a sure issue of it, built a jail and added a wing to either side of the town hall, but “the greatest laid schemes of mice and males gang af’t aglee.” The fellows that did all this mischief have been turned down by the people and factors took their normal shape and Charlestown was once more the county seat.

Shepherd University started when the county seat of Jefferson County, West Virginia, was moved from Shepherdstown to Charles Town in July 1871. On February 27, 1872, the Legislature of West Virginia passed the following act: “That a branch of the State Regular School be and the same is hereby established at the building known as Shepherd College, in Shepherdstown, in the county of Jefferson.”

59_RD’s descendant, Shepherd Brooks

RD’s descendant, Shepherd Brooks, produced it final when he deeded the property and building over to the School and a 3-particular person board of trustees to maintain it.

As they say, settings reverse, the tide of life had gone out – and – came back in once more.