Eurotech 710SLLY Mutli Axis CNC Turning Center with 24 Reside Tools completing a component.

Video Rating: 5 / 5

Aluminium Machining China

Eurotech 710SLLY Mutli Axis CNC Turning Center with 24 Reside Tools completing a component.

Video Rating: 5 / 5

A handful of good cnc turning center images I located:

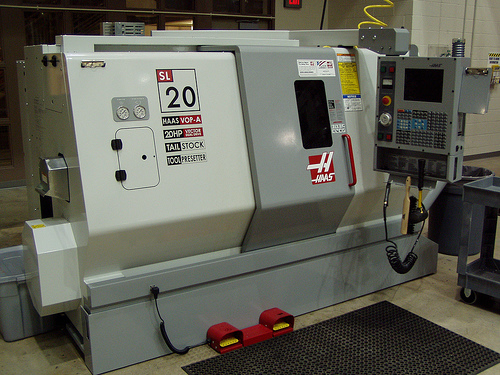

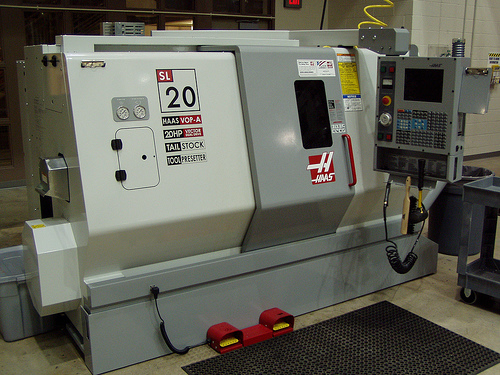

CNC Turning Center

Image by spangineer

A modest CNC turning center, in the Leonhard Building at Penn State.

Okuma's New VTM-2000YB Multitasking CNC Turning Center Offers Heavy …

At IMTS 2014, Okuma will introduce its new VTM-2000YB multitasking CNC turning center, which offers heavy-duty construction for big parts machining. The extreme rigidity and effective cutting capabilities of this machine make it ideal for machining …

Study much more on Robotics Tomorrow

The Dawn of the Sensible Factory

For instance, in CNC turning operations, a number of diverse machines are employed with an external controller, such as conveyors or robotic arms to move elements from machine to machine and align them under the guidance of industrial cameras before …

Read a lot more on Quality Magazine

Additive Manufacturing Expert EOS Joins Commonwealth Center for Advanced …

In the case of a close to-net DMLS portion, a milling or CNC cutting procedure might be far more suitable. And the resulting production line may be … The 62,000 square-foot facility at the Center's Prince George County property includes computational software program and …

Read far more on ENGINEERING.com

Rockwell and Fanuc announce international collaboration

Robomachines are Fanuc's robotic machining centres, which contain injection moulding, vertical milling and EDM (electrical discharge machining) systems. The principal initial influence of the new collaboration is expected be in the automotive industry, exactly where …

Read a lot more on Drives & Controls

IMTS 2014 Conference: Re-evaluating the EDM Approach

Till not too long ago, several companies of titanium components have deemed electrical discharge machining (EDM), either fully off limits, or to be employed as a main process coupled with a secondary operation. A lot of instances, the secondary operation is …

Read more on Today’s Power Solutions

CNC Software participates in 3rd annual MFG Day

Tolland, Connecticut – CNC Application, Inc., creators of Mastercam CAD/CAM software, will host an open residence at its manufacturing facility situated at 671 Old Post Road, Tolland, Conn. to celebrate Manufacturing Day. The open house will be held on Friday, …

Read a lot more on Aerospace Manufacturing and Design and style

Check out these precision manufacturing business pictures:

Steven F. Udvar-Hazy Center: south hangar panorama, such as B-29 Superfortress “Enola Gay”, Grumman F6F-3 Hellcat, among other folks

Image by Chris Devers

See much more photos of this, and the Wikipedia report.

Particulars, quoting from Smithsonian National Air and Space Museum: Steven F. Udvar-Hazy | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of Planet War II and the 1st bomber to residence its crew in pressurized compartments. Although developed to fight in the European theater, the B-29 found its niche on the other side of the globe. In the Pacific, B-29s delivered a assortment of aerial weapons: traditional bombs, incendiary bombs, mines, and two nuclear weapons.

On August 6, 1945, this Martin-built B-29-45-MO dropped the very first atomic weapon employed in combat on Hiroshima, Japan. 3 days later, Bockscar (on show at the U.S. Air Force Museum near Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance climate reconnaissance aircraft that day. A third B-29, The Excellent Artiste, flew as an observation aircraft on both missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Nation of Origin:

United States of America

Dimensions:

All round: 900 x 3020cm, 32580kg, 4300cm (29ft 6 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Components:

Polished all round aluminum finish

Physical Description:

4-engine heavy bomber with semi-monoqoque fuselage and higher-aspect ratio wings. Polished aluminum finish general, standard late-Globe War II Army Air Forces insignia on wings and aft fuselage and serial quantity on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on reduced left nose.

• • • • •

See much more photos of this, and the Wikipedia write-up.

Particulars, quoting from Smithsonian National Air and Space Museum: Steven F. Udvar-Hazy | Grumman F6F-3 Hellcat:

The Grumman F6F Hellcat was originally conceived as an sophisticated version of the U.S. Navy’s then present front-line fighter, the F4F Wildcat (see NASM collection). The Wildcat’s intended replacement, the Vought F4U Corsair (see NASM collection), first flown in 1940, was showing excellent guarantee, but development was slowed by troubles, such as the crash of the prototype.

The National Air and Space Museum’s F6F-three Hellcat, BuNo. 41834, was built at Grumman’s Bethpage, New York, factory in February 1944 under contract NOA-(S)846. It was delivered to the Navy on February 7, and arrived in San Diego, California, on the 18th. It was assigned to Fighter Squadron 15 (VF-15) on USS Hornet (CV12) bound for Hawaii. On arrival, it was assigned to VF-3 where it sustained harm in a wheels-up landing at NAS Barbers Point, Hawaii. Right after repair, it was assigned to VF-83 where it was employed in a instruction part until February 21, 1945. Soon after many transfers 41834 was converted to an F6F-3K target drone with the installation of sophisticated radio-control equipment. It was painted red with a pink tail that carried the number 14. Its mission was to be employed in Operation Crossroads – the atomic bomb tests at Bikini Atoll. It flew on June 24, 1946, with a pilot, on a practice flight and was launched, unmanned, quickly after the initial bomb test. Instrumentation on board and photographic plates taped to the control stick obtained information on radioactivity. Three far more manned flights preceded the final unmanned flight on July 25, 1946, which evaluated the 1st underwater explosion. Records indicate that exposure of this aircraft to the radioactive cloud was minimal and residual radiation is negligible.

F6F-3K 41834 was transferred to NAS Norfolk and logged its last flight on March 25, 1947, with a total of 430.two flying hours. It was assigned to the National Air Museum on November 3, 1948, and remained at Norfolk till October 4, 1960, when it was moved by barge to Washington and placed in storage. In 1976 this Hellcat was loaned to the USS Yorktown Museum at Charleston, South Carolina. A superficial restoration was performed at the museum, but because of the harsh atmosphere and its poor situation the Hellcat was returned to NASM on March 16, 1982. In 1983, it was sent to Grumman Aerospace where a team of volunteers totally restored the aircraft. In 1985, it was shipped back to the Paul E. Garber Preservation, Restoration and Storage Facility in Suitland, Maryland, and place in storage. NASM’s F6F-3 Hellcat is scheduled to be displayed in the new Steven F. Udvar-Hazy center at Dulles International Airport in Virginia in 2004.

Transferred from the United States Navy.

Manufacturer:

Grumman Aircraft Engineering Corporation

Date:

1943

Nation of Origin:

United States of America

Dimensions:

All round: 338 x 1021cm, 4092kg, 1304cm (11ft 1 1/16in. x 33ft five 15/16in., 9021.2lb., 42ft 9 3/8in.)

Physical Description:

Heavy armor plate, reinforced empennage, R-2800-10W engine, spring tabs on the ailerons (enhanced maneuverability), could carry rockets as effectively as bombs.

P & R started its CNC machining workshop in 1999 from Bhavnagar (Gujarat India). Our company has established itself as the leading manufacturer and supplier …

Most popular cnc lathe turning eBay auctions:

[wprebay kw=”cnc+lathe+turning” num=”3″ ebcat=”-1″]

[wprebay kw=”cnc+lathe+turning” num=”4″ ebcat=”-1″]

[wprebay kw=”cnc+lathe+turning” num=”5″ ebcat=”-1″]

Most popular cnc turning eBay auctions:

[wprebay kw=”cnc+turning” num=”6″ ebcat=”-1″]

[wprebay kw=”cnc+turning” num=”7″ ebcat=”-1″]

CNC China Turning Center with Twin Spindles and Live Tooling (Goodway GTS-200XY). Watch the GTS-200XY lathe’s features and capabilities as it turns and mills a com…

Video Rating: 4 / 5

Video showing our Samsung SL25ASY CNC China Lathe in action. For information on how MAPCO China Manufacturing can help with your CNC precision turning and milling requir…

Video Rating: 5 / 5

Some recent cnc turning center auctions on eBay:

[wprebay kw=”cnc+turning+center” num=”0″ ebcat=”-1″]

[wprebay kw=”cnc+turning+center” num=”1″ ebcat=”-1″]

[wprebay kw=”cnc+turning+center” num=”2″ ebcat=”-1″]