Surface China Grinding Stainless Steel on eBay:

[wprebay kw=”surface+grinding+stainless+steel” num=”0″ ebcat=”-1″]

Aluminium Machining China

Surface China Grinding Stainless Steel on eBay:

[wprebay kw=”surface+grinding+stainless+steel” num=”0″ ebcat=”-1″]

Some recent electric discharge machining edm auctions on eBay:

[wprebay kw=”electric+discharge+machining+edm” num=”2″ ebcat=”-1″]

[wprebay kw=”electric+discharge+machining+edm” num=”3″ ebcat=”-1″]

Check out these wire cutting services images:

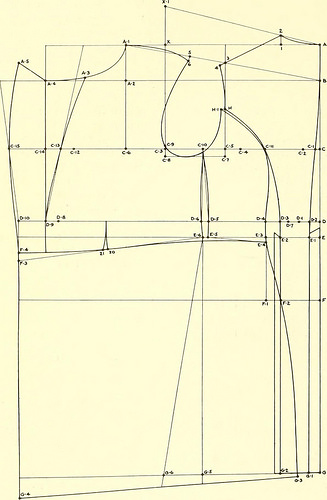

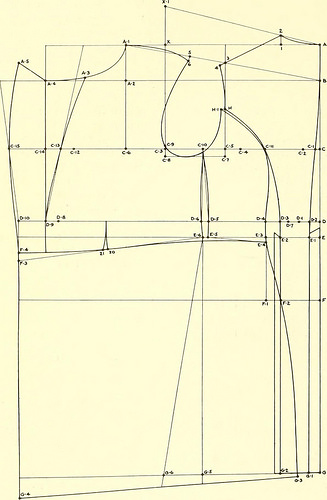

Image from page 75 of “Popular gentleman system for cutting and designing of men’s garments” (1917)

Image by Internet Archive Book Images

Identifier: populargentleman00popu

Title: Popular gentleman system for cutting and designing of men’s garments

Year: 1917 (1910s)

Authors: Popular gentleman service company, Philadelphia. [from old catalog]

Subjects: Tailoring

Publisher: Philadelphia, Pa., Popular gentleman service company

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

the collar size plus IVi inchfrom A to 2 and from A-1 down to getA-3. A-3 to A-4 is 11/4. inch. Shape from A-4 thru C-14 and D-10 down. D-10 to F-3 is 3% inches. Draw a line from E-6 to F-3. F-4 is %. of an inch above F-3. Shape from E-4 to F-4 as diagram. Square down from E-6 to get G-5. G-5 to G-6 is 1-6 breast. Draw a line from E-6 to G-6. Open the skirt as from E-6 to G-5 and G-6for flare, this can be more or less forstyle. The over shoulder and strap measures areapplied the same as for regular coat andalso the sleeve. THE COLLAR. Measure your neck from A to 2 and from A-1to A-3 and draft. The neck size is 8I/2 inches. A to B is 8I/2 inches. A to C is half the neck size or 414 inches. Square out from C and down from B to lo-cate D. D to E is 11/2 inch. A to F is 11/2 inch. Square in from F. D to G is the neck size. Square up l/. inch from G to get H. Draw a line from H to E. Shape from H to E and from G to D as dia-gram. This finishes the draft. 73 DOUBLE BREASTED FROCK FOR STOUT

Text Appearing After Image:

Breast 44 in. Waist 44 in. Waist depression 2 in. The measurements are as follows :- Scye depth 10 in. Waist length __ 17 in. FuU length 41 in. Seat 45. Neck size 16i/>. Blade 131/4 in. Over shoulder 19% in.Strap 131/2 in. 74 Square down and out from A. A to B is Vt! breast plus % of an inch. A to C is the scye depth. A to D is the waist length. D to E is IV2 inch for fashionable waist length.E to F is 6 inches.A to G is the full length.Square out from C, D, E, F and G.D to D-1 is the waist depression.D-2 is half way between D and D-1.Square down from D-2 to locate E-1 and G-1.Draw a line from E-1 to B to locate C-1.E-1 to E-2 is Vs breast.Square down from E-2 to locate G-2.C-1 to C-2 is 11/4 inch.C-2 to C-3 is the blade measure.Square up from C-3 to locate X.X to X-1 is i/j! breast plus 1 inch.Draw a line from X-1 to A.A to 1 is Vs breast plus 1 inch.Square up from 1 to locate 2.C-4 is half way between C-3 and C-1.C-4 toC-5is 11/2 inch.Square up from C-5.C-6 is one half the width

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

School partners to teach 'real-world skills'

Students will be able to use equipment provided by Zipper Labs, such as a 3-D printer and China CNC machine, to bring their ideas and prototypes to reality. Defining design thinking as empathy-based problem solving, Dirkse said the course will show students …

Read more on Grand Rapids Business Journal (subscription)

Machining Centers Offer High Repeat Accuracy

Available from Starrag, Bumotec SA's S-191 Linear series of CNC turning/milling centers uses linear motors to ensure maximum precision and reliable repeat accuracy when processing gold, silver or platinum for producing parts such as watch components, …

Read more on Modern China Machine Shop

http://www.g-mach.co.uk/ We produce precision machined components China to customer specification. The China company was established in 1993 on the back of over 25 years…

http://www.paprecision.com/ Very best importance of cutting speed As well as feed for precision machining? Concept of cutting speed is — within the particul…

Video Rating: 5 / 5

Concept to Installation General & Specialized Custom China Manufacturing Process A division of Atlanta Attachment Company Proudly Made in the USA! — Contact: sal…

cnc milling turning eBay auctions you should keep an eye on:

[wprebay kw=”cnc+milling+turning” num=”6″ ebcat=”-1″]

[wprebay kw=”cnc+milling+turning” num=”7″ ebcat=”-1″]

[wprebay kw=”cnc+milling+turning” num=”8″ ebcat=”-1″]

[wprebay kw=”cnc+milling+turning” num=”9″ ebcat=”-1″]

Disston Precision provides quality Blanchard or rotory China grinding services of circular or rectangular products. This process is a quick way to grind large surf…

Video Rating: 5 / 5

A few nice component manufacturing company images I found:

Cycle Components China Manufacturing Company Ltd three wheeler

Image by exfordy

De Dion Bouton engine behind the rear axle made pulling a wheelie rather too easy.

[Airplane Cloth Room, Pepperell China Manufacturing Company]

Image by SMU Central University Libraries

Title: [Airplane Cloth Room, Pepperell China Manufacturing Company]

Creator: Richie, Robert Yarnall, 1908-1984

Date: February 1943

Series: Series 6: Negatives and Color Transparencies

Negative Series: 2509

Place: San Antonio, Texas

Description: Workers assembling aircraft wing and tail components by sewing aircraft covering fabric over prepared aircraft open structures.

Physical Description: 1 negative: film, black and white; 12.6 x 10.1 cm

File: ag1982_0234_2509_28_pepperellmfgco_sm_opt.jpg

Rights: Please cite Southern Methodist University, Central University Libraries, DeGolyer Library when

using this image file. A high-quality version of this file may be obtained for a fee by contacting

degolyer@smu.edu.

For more information, see: digitalcollections.smu.edu/cdm/ref/collection/ryr/id/2434

Millinocket Fabrication and China Machine owners say foundry growing, looking to …

“We have two to three years before things start turning over, but we like to get those people in and training while our workforce is still here,” he added. In fact … The company specializes in the custom fabrication and machining of parts weighing up …

Read more on Bangor Daily News

Sandvik Coromant offers systems for almost all aerospace machining challenges

… combustion casings and blisks make for challenging machining. Here, Sandvik says that producing difficult-to-access pockets and grooves necessitates 90°, 45° or T-shape Corocut angled inserts with sharp, ground geometries, while for turning …

Read more on The Engineer

Ketzenberger: Scrap yard married tradition, technology

Rounding past the shipping dock, you'll see housings and blades from jet engines among other big bales of shavings left over from machining processes. This is where the more exotic metals are kept and the area is just behind the office where third …

Read more on Indianapolis Star