A few good edm service photos I located:

Refshaleoen 20131022_13

Image by News Oresund

Refshaleøen, Copenhagen harbour, Eurovision Island 2014 – Eurovision Song Contest.

Photo: News Øresund – Susan Daniels

© News Øresund

Wikipedia: On two September 2013, Danmarks Radio (DR) announced that the Eurovision Song Contest 2014 will take place at B&W Hallerne. The surrounding location will be transformed into Eurovision Island, an Olympic Park style complex which will house amenities and the Press Centre for the entirety of the contest.[6]

Refshaleøen, originally an island in its own right but now annexed to the bigger island of Amager, is a former industrial internet site in the harbor of Copenhagen, Denmark. For much more than a hundred years, it was residence to the shipyard Burmeister & Wain which closed in 1996.

Refshaleøen is regularly employed as a venue for events and festivals. In 2013, I 2013 the region played host to the heavy metal festival Copenhell, the electronic music festival EDM 2013, Scandinavian Reggae Festival, MAD Food Symposium (part of Copenhagen Cooking), Refshalen Music Festival and Asteroiden theatre festival.

Internet site surface area is approx. 500,000 sqm. Considering that the shipyard’s bankruptcy in 1996, the area has undergone important changes. The abandoned buildings are now house to a mixture of inventive entrepreneurs, little craft, flea markets, storage facilities and cultural and recreational uses.

The residents contain Asterions Husm a theatre, AMASS,[3] a restaurant opened by Mathew Orlando, former head chef at Noma,[four] the art gallery YARD and the inventive neighborhood Skabelonloftet.[five]

Since April 2011 there are once more both at the old shipyard. Copenhagen Yacht Solutions has opened the first Danish Yacht garage on the island – an indoor Marina for motorboats on the American model..[2]

The private spaceflight company Copenhagen Suborbitals operates on Refshaleøen.

Detta verk av News Øresund är licensierat under en Inventive Commons Erkännande 3. Unported-licens (CC BY 3.). Bilden får fritt publiceras below förutsättning att källa anges (Foto: News Øresund + fotografnamn).

The image can be used freely beneath the prerequisite that the supply is provided .

News Øresund, Malmö, Sweden.

www.newsoresund.org.

News Øresund är en oberoende regional nyhetsbyrå som ingår i projektet Øresund Media Platform som drivs av Øresundsinstituttet i partnerskap med Lunds universitet och Roskilde Universitet och med delfinansiering från EU (Interreg IV A Öresund) och 14 regionala icke kommersiella aktörer.

Refshaleoen 20131022_11

Image by News Oresund

Refshaleøen, Copenhagen harbour, Eurovision Island 2014 – Eurovision Song Contest.

Photo: News Øresund – Susan Daniels

© News Øresund

Wikipedia: On 2 September 2013, Danmarks Radio (DR) announced that the Eurovision Song Contest 2014 will take spot at B&W Hallerne. The surrounding location will be transformed into Eurovision Island, an Olympic Park style complex which will home amenities and the Press Centre for the entirety of the contest.[six]

Refshaleøen, initially an island in its own correct but now annexed to the larger island of Amager, is a former industrial website in the harbor of Copenhagen, Denmark. For far more than a hundred years, it was property to the shipyard Burmeister & Wain which closed in 1996.

Refshaleøen is frequently utilized as a venue for events and festivals. In 2013, I 2013 the region played host to the heavy metal festival Copenhell, the electronic music festival EDM 2013, Scandinavian Reggae Festival, MAD Meals Symposium (part of Copenhagen Cooking), Refshalen Music Festival and Asteroiden theatre festival.

Website surface location is approx. 500,000 sqm. Since the shipyard’s bankruptcy in 1996, the area has undergone significant alterations. The abandoned buildings are now property to a mixture of creative entrepreneurs, modest craft, flea markets, storage facilities and cultural and recreational utilizes.

The residents include Asterions Husm a theatre, AMASS,[3] a restaurant opened by Mathew Orlando, former head chef at Noma,[4] the art gallery YARD and the inventive neighborhood Skabelonloftet.[5]

Given that April 2011 there are again each at the old shipyard. Copenhagen Yacht Services has opened the 1st Danish Yacht garage on the island – an indoor Marina for motorboats on the American model..[two]

The private spaceflight company Copenhagen Suborbitals operates on Refshaleøen.

Detta verk av News Øresund är licensierat below en Inventive Commons Erkännande 3. Unported-licens (CC BY three.). Bilden får fritt publiceras under förutsättning att källa anges (Foto: News Øresund + fotografnamn).

The image can be utilized freely beneath the prerequisite that the source is provided .

News Øresund, Malmö, Sweden.

www.newsoresund.org.

News Øresund är en oberoende regional nyhetsbyrå som ingår i projektet Øresund Media Platform som drivs av Øresundsinstituttet i partnerskap med Lunds universitet och Roskilde Universitet och med delfinansiering från EU (Interreg IV A Öresund) och 14 regionala icke kommersiella aktörer.

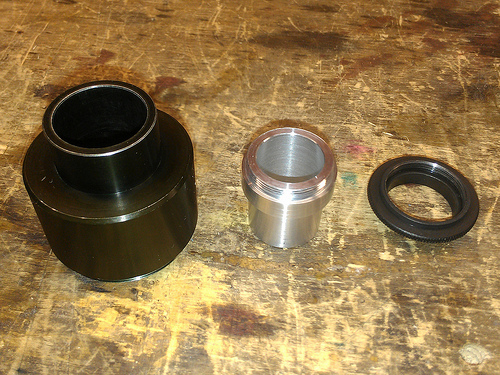

Refshaleoen 20131022_14

Image by News Oresund

Refshaleøen, Copenhagen harbour, Eurovision Island 2014 – Eurovision Song Contest.

Photo: News Øresund – Susan Daniels

© News Øresund

Wikipedia: On two September 2013, Danmarks Radio (DR) announced that the Eurovision Song Contest 2014 will take location at B&W Hallerne. The surrounding location will be transformed into Eurovision Island, an Olympic Park style complicated which will house amenities and the Press Centre for the entirety of the contest.[6]

Refshaleøen, initially an island in its own correct but now annexed to the larger island of Amager, is a former industrial website in the harbor of Copenhagen, Denmark. For far more than a hundred years, it was home to the shipyard Burmeister & Wain which closed in 1996.

Refshaleøen is frequently used as a venue for events and festivals. In 2013, I 2013 the location played host to the heavy metal festival Copenhell, the electronic music festival EDM 2013, Scandinavian Reggae Festival, MAD Meals Symposium (portion of Copenhagen Cooking), Refshalen Music Festival and Asteroiden theatre festival.

Internet site surface region is approx. 500,000 sqm. Since the shipyard’s bankruptcy in 1996, the location has undergone considerable adjustments. The abandoned buildings are now residence to a mixture of creative entrepreneurs, small craft, flea markets, storage facilities and cultural and recreational utilizes.

The residents consist of Asterions Husm a theatre, AMASS,[3] a restaurant opened by Mathew Orlando, former head chef at Noma,[four] the art gallery YARD and the inventive neighborhood Skabelonloftet.[5]

Considering that April 2011 there are again each at the old shipyard. Copenhagen Yacht Services has opened the initial Danish Yacht garage on the island – an indoor Marina for motorboats on the American model..[2]

The private spaceflight business Copenhagen Suborbitals operates on Refshaleøen.

Detta verk av News Øresund är licensierat below en Creative Commons Erkännande 3. Unported-licens (CC BY 3.). Bilden får fritt publiceras under förutsättning att källa anges (Foto: News Øresund + fotografnamn).

The image can be employed freely under the prerequisite that the supply is provided .

News Øresund, Malmö, Sweden.

www.newsoresund.org.

News Øresund är en oberoende regional nyhetsbyrå som ingår i projektet Øresund Media Platform som drivs av Øresundsinstituttet i partnerskap med Lunds universitet och Roskilde Universitet och med delfinansiering från EU (Interreg IV A Öresund) och 14 regionala icke kommersiella aktörer.