Intorex offers the most recent CNC wood machining centre TMC-1500 / 3000 capable of producing either turned or shaped furniture and joinery elements by means of 5 i…

Machining

Lastest Precision Machining Company News

Late organization owner who began company in garage 80 years ago is honored

The organization has become a completely integrated supplier of screw machining, CNC machining and precision grinding with McCullough's leadership. McCullough is an active member of JAMA, serving on the Board of Directors and as a member of the Academy for …

Read far more on MLive.com

Finisar Introduces WaveShaper 1000/SP Test Instrument

This new module shapes femtosecond and brief picosecond optical pulses in fiber laser systems in precision micromachining, medical and spectroscopy applications, for example. The new 1µm WaveShaper module enables steady … LightSmyth(TM) Technologies …

Read far more on MarketWatch

New Industrial Maintenance Plan Hopes To Create Skilled Workers Region …

Just two years ago the Pittsylvania Profession and Technical Center started their precision machining plan. Companies in the region had a want for workers with that ability, and the center delivered. "I'll certainly attempt to get a job in this field. It's a …

Study a lot more on WSET

CNC Wire Reduce EDM: Wire Erosion Machining for aerospace, defence, healthcare, motorsport, satellite

The Di-Spark Group are a globe-class, 24/7 EDM machining subcontract business, supplying AS9100(c) and SC21 EDM Wire Erosion machining The Di-Spark Group had been…

Lastest Electric Discharge Machining Edm News

1 Should-Watch Interview for 3D Systems Corporation and Stratasys, Ltd. Investors

But then there's pressure relief: That's a heat treatment. It's removing the supports and anchors, which can call for EDM [electrical discharge machining] or a band saw or other tools. It's CNC [personal computer numerical handle] machining to increase the surface …

Study a lot more on Motley Fool

GF Machining Solutions Unveils Devoted Mold Producing Wire EDM Series

Items range from electric discharge machines, higher-speed and higher-overall performance milling machines, like clamping and palletization systems, and 3D laser surface texturing machines, to services, spare parts and expendable components, consumables and …

Read much more on ENGINEERING.com

Magnum Machining awarded grant

Magnum Machining awarded grant

Positioned in Deerwood and Ironton in Crow Wing County, Magnum Machining styles, engineers, manufactures and assembles precision personal computer numeric controlled (CNC) items and elements. Magnum Machining currently employs 59 workers at the …

Read a lot more on Aitkin Independent Age

Cube invests in growth with Lloyds package

Neil Clifton, managing director at Cube, mentioned: "We had been experiencing a high level of demand for our large CNC machining elements and, in order to fulfil this, we needed to enhance our manufacturing capabilities by getting new machinery.

Read much more on Insider Media

Lloyds Bank backs Black Nation manufacturer's expansion plans

Managing director Neil Clifton, Managing Director at Cube Precision Engineering, stated: "We had been experiencing a high level of demand for our big CNC machining components and, in order to fulfil this, we necessary to enhance our manufacturing …

Study a lot more on Birmingham Post

Wire Technologies Providing Metal Fabrications and Machining for Clients

Wire Technologies Providing Metal Fabrications and Machining for Consumers

Wire Technologies operates out of a 5,000 square foot facility in Boca Raton, Florida, where they are a complete service EDM machining shop. As each business has diverse specifications for machine cutting, Wire Technologies serves healthcare fields, military …

Read more on Digital Journal

BobCAD-CAM, Inc. Releases New Wire EDM CAD/CAM Software program For CNC Wire …

Their CAD/CAM products boost workflow efficiency by streamlining the method of deciding on tools, supplies and cutting techniques which can be extremely time consuming and produces the numeric code that the machine needs to actually machine the component …

Study far more on Machine Tools On the internet (press release)

CNC Drehteile CNC Machining Parts Supplier in china Vincent Components Inc

CNC department of Vincent Parts Inc.Good Quality with reduce value,Tiny order accept. Your very good decision for outsource,truly reduce your purchaser cost. 2013 …

Video Rating: five / 5

Corporate video for ANCA. Makers of CNC Tool Grinding machines.

Video Rating: four / 5

Nice Machining Supplier images

Check out these machining supplier pictures:

THE DOT MOTORCYCLE.VILLIERS SINGLE CYLINDER TWO STROKE. UK.

Image by ronsaunders47

The name DOT stands for "Devoid of Trouble".

The Burnard Scott Wade Years (1932 – 1984)

In 1920 Thomas Sawyer joined the organization and, following Reed departed from the organization in 1925, Sawyer oversaw additional success for the Dot marque in competition but with the onset of the 1930’s recession production slowed and ultimately ceased in 1932 When Sawyer passed handle of the company to a young Burnard Scott Wade. Burnard Wade kept the organization going via the 1930’s with a line of pedal powered three-wheel delivery trucks developed for the niche markets of milk delivery and ice cream vending. With the onset of World War II the Government awarded Dot a contract for the production of these economical delivery autos which have been shipped around the world. During the tedious “fire watching ” duty throughout the Manchester Blitz Wade sketched out ideas for a similar car powered by a tiny two-stroke engine and effectively developed this into the Dot Motor Truck which could be developed in numerous guises to meet the distinct needs of the industry for a low cost powered delivery car. Such was the demand that a lucrative Dot Business was able to re-enter the motorcycle market in 1949 with a utilitarian 2-stroke machine with a 200cc Villiers engine which sold nicely in the export market place and numerous are still identified today in Scandinavia, Canada and Australia. The temptation for Dot to generate a sporting machine was also sturdy to resist and Wade developed a modest, low-cost two-stroke machine which could be ridden on the road on an everyday basis but, with minor alternations such as taking off the lights, could compete in the common scrambles and trials events of the day. The “Trials Scrambler” was introduced in 1951 and in a quick time riders of the calibre of Bill Barugh and Terry Cheshire and hundreds of club riders had realised that such nimble lightweight machines had the beating of the bigger machines previously predominant in the sport and ushered in the contemporary lightweight competition bikes. By a coincidence of fate 1951 was also the year that the Dot founder, Harry Reed, died. Dot also place some effort into building a lightweight Road Racing machine, again entering the TT and won the Team Award in the 1951 Ultra Lightweight 125cc TT, the only such win by a British Manufacturer. The actual demand even so was for Trials and Scrambles and all through the Fifties and into the early Sixties Dot had been a considerable force to be reckoned with in Scrambles and Trials events each in the top events with Operates Riders such as Eric Adcock, Jonnie Griffiths, Ernie Gree and pat Lamper and in a myriad of nearby events where the ordinary clubman could afford and ride comparable machines to those campaigned by the Factory Team. Ultimately nonetheless Dot found it increasingly tough to compete with the larger Motorcycle Factories and the demise of their major engine supplier, Villiers, and the escalating quantity of foreign imports spelled the end of large scale production.

The Dot Factory still exists at Ellesmere Street, Hulme in Manchester with the company producing and selling a variety of spares for postwar machines. The Dot Motorcycle Club actively caters for owners and enthusiasts, publishes a magazine and attends most significant classic motorcycle events. A lot of the material for this post comes from “Devoid of Trouble” , the history of Dot Motorcycles written by the Official Dot Historian, Ted Hardy. The book provides far more detail of Dot and is accessible by way of the Club site www.dot-motorcycle-club.co.uk.

Green Legos

Image by [ Roberto Bouza ]

LEGO Store – Orlando, FL

About it

The Lego Group began in the workshop of Ole Kirk Christiansen, a carpenter from Billund, Denmark, who started generating wooden toys in 1932. In 1934 his firm came to be known as Lego. It expanded to generating plastic toys in 1940. In 1949 Lego started creating the now well-known interlocking bricks, calling them "Automatic Binding Bricks". These bricks have been based largely on the design and style of Kiddicraft Self-Locking Bricks, which had been released in the United Kingdom in 1947. Lego modified the design of the Kiddicraft brick right after examining a sample given to it by the British supplier of an injection-moulding machine that the business had purchased. The bricks, manufactured from cellulose acetate, have been a improvement of traditional stackable wooden blocks that locked together by implies of a number of round studs on leading and a hollow rectangular bottom. The blocks snapped collectively, but not so tightly that they required extraordinary work to be separated.

The business name Lego was coined by Christiansen from the Danish phrase leg godt, which indicates play effectively. The name could also be interpreted as "I put collectively" and "I assemble" in Latin, although this would be a somewhat forced application of the general sense "I collect I gather I understand" the word is most utilized in the derived sense "I read".

The Lego Group’s motto is kun det bedste er godt nok which indicates ‘only the best is good enough’. This motto was produced by Ole Kirk to encourage his staff by no means to skimp on high quality, a value he believed in strongly. The motto is nevertheless used inside the organization these days.

The use of plastic for toy manufacture was not hugely regarded by retailers and shoppers of the time. Many of the Lego Group’s shipments were returned soon after poor sales it was thought that plastic toys could by no means replace wooden ones.

By 1954 Christiansen’s son Godtfred Kirk Christiansen had become the junior managing director of the Lego Group. It was his conversation with an overseas purchaser that struck the thought of a toy system. Godtfred saw the immense potential in Lego bricks to become a program for creative play but the bricks nevertheless had some problems from a technical standpoint: their locking capability was limited and they have been not really versatile. In 1958 the modern brick style was created but it took another 5 years to discover the proper material for it. The modern day Lego brick was patented on January 28, 1958 bricks from that year are nevertheless compatible with current bricks.

The shot

A couple of days ago the family members and I went to Orlando to go to. On 1 of those days we decided to go to Downtown Disney, just simply because the tiny 1 could go and see a bunch of toys of Mickey, Pluto and all these cute guys. I’m always with my camera (or attempt to) so I can take benefit of every moment that I have to make a very good shot. To my delight I went to the LEGO store and start shooting some photographs there. I love LEGO’s considering that I was a little kid, they are the very best toys ever!!! So walking via the shop I stumble upon the LEGO Wall, then I decided to insert the camera in one of the cubby holes and take a couple of images with the wide angle lens, to my satisfaction this shot came out just ideal (or at least I consider so).

I hope you like the shot as a lot as I do.

Thank you.

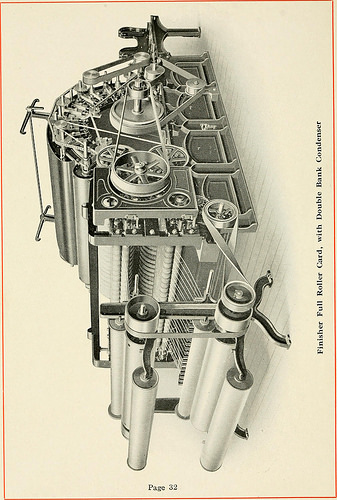

Image from page 35 of “1919 illustrated and descriptive catalog of Whitin cotton waste machinery” (1919)

Image by Web Archive Book Pictures

Identifier: illustratedd1919whit

Title: 1919 illustrated and descriptive catalog of Whitin cotton waste machinery

Year: 1919 (1910s)

Authors: Whitin Machine Performs (Whitinsville, Mass.)

Subjects: Cotton machinery

Publisher: Whitinsville, MA : Whitin Machine Performs

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click right here to view book on the internet to see this illustration in context in a browseable on the web version of this book.

Text Appearing Just before Image:

or without metallic breasts usually with a fancy. If a doubleris utilized among breaker and finisher cards, the breaker is equippedwith a two, four or six-coiler front or with belt conveyor front andone coiler. When a cross-feed is utilised, the sliver is taken directlyfrom the breaker card and laid either straight or diagonally acrossthe back of the finisher. Production: 200 to 400 pounds per day of ten hours. Speed of Cylinder: 100 to 165 r. p. m., based on theclass of stock utilized. Size of Driving Pulleys: 20 x 3, 24 x four, or 30 x 5. Energy: From h. p. to three h. p., depending on speed andproduction preferred. Page 30 Clothing: Based on class of function and grade of stock tobe run. Counts of wire and foundations to suit. Supplies: Roving Cans. Extras: Supplier as ordered.Automatic Feed,Double Lap Back,Metallic Breast,Belt Shipper. Floor Space: 48 card, 9 1 extended, 7 7 wide. Weights, 48 Card. Domestic: Export: Gross, 9500 pounds, Gross, 10000 pounds, Net, 8200 pounds. Cubic feet, 500. Web page 31

Text Appearing Right after Image:

FINISHER Full ROLLER CARD The Finisher Cards are of the complete roller variety, equivalent in con-struction to the breaker card with 50 Diameter Cylinder in widthsof 40, 45, 48, 51 and 61. The arches and bearings are so con-structed that really accurate settings can be made and retained. Allrolls have shell ends. Metallic breasts can be applied to the finishercards when desired, or when the class of stock demands them andall finisher cards are equipped with a fancy roll. Exactly where DerbyDoublers are utilized, the finisher cards are constructed with either single ordouble lap backs, and the lap is taken straight from the lap head tothe back of the finisher card. When the doubler is omitted, a cross-feed is utilized, the cards getting connected either tandem or parallel.The finisher card is built with either a single or double doffer. Witha single doffer, the roving is delivered to a single-bank condenser, orto a four-bank tape condenser. Where the double doffer is employed,the roving is delivered to a double-bank conde

Note About Pictures

Please note that these photos are extracted from scanned page pictures that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not completely resemble the original work.

What is EDM -Electric Discharge Machining and Wire Cutting

For more data please get in touch with Xact Wire EDM Corporation at http://www.xactedm.com.

Video Rating: five / 5

Lastest Precision Machining China News

Thrustmaster Expands Thruster Factory Once again

… the item testing area, add an on-internet site paint and blast facility, develop a new fabrication shop, expand machine shop operations, expand the assembly region and add a multitude of upgrades that will lend to the efficiency and precision of thruster …

Study much more on The Maritime Executive (press release)