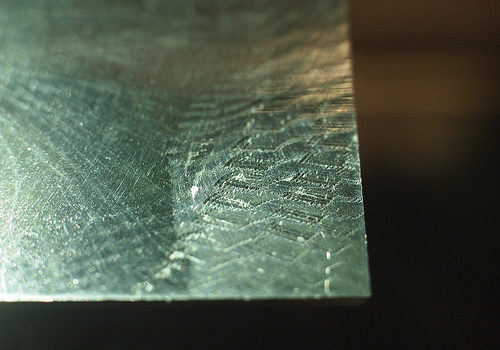

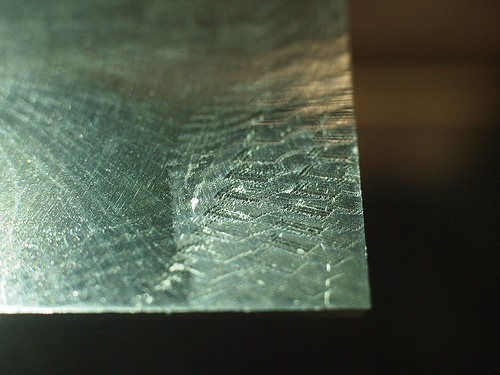

Some cool cnc metal cutting photos:

Traces of vibration

Image by Bushman.K

This is close-up photo of relatively thin (.060"= 1.5mm) piece of stock on the bottom of part. When you are machining some component from the prime side, then flipping it upside down, you typically have some type of rectangular "flange" there. removal of this extra material employing big diameter facemill produces wide thin functions. These features can most likely start off vibrating, when they are thin and wide sufficient. Therefore, deflected piece of metal can get into the moving cutter and brake it. Aluminum does not appear to be tough enough to do that, but steel does for sure. Here you can see, what kind of toolmarks does the cutter make on the vibrating machined surface.

To stay away from this situation, it really is far better to run contour reduce around the element to remove these thin hanging attributes. One more way is to make an undercut around the bounding shape of component to be capable to break off that further material with pliers, for instance.

cuts

Image by Luiza