Some recent precision cnc China turned components auctions on eBay:

[wprebay kw=”precision+cnc+turned+components” num=”0″ ebcat=”-1″]

Aluminium Machining China

Some recent precision cnc China turned components auctions on eBay:

[wprebay kw=”precision+cnc+turned+components” num=”0″ ebcat=”-1″]

http://www.aliexpress.com/store/418459 this is our factory English net http://facebook.com/luochaoaaa this is our facebook http://luochaoaaa.1688.com this is…

Video Rating: 0 / 5

Some recent cnc turned component auctions on eBay:

[wprebay kw=”cnc+turned+component” num=”0″ ebcat=”-1″]

Some cool cnc China turned parts images:

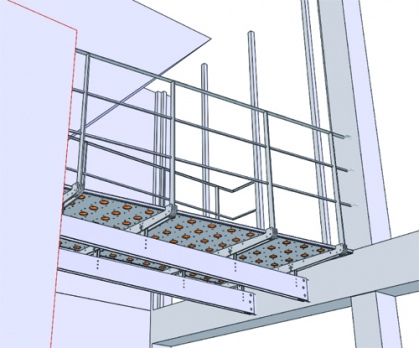

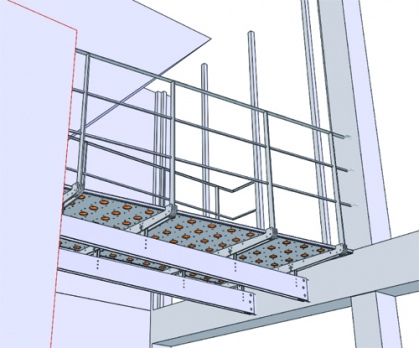

Catwalk SolidWorks model view 01

Image by Caliper Studio

SolidWorks parametric model snapshot.

Designed for a multimedia design firm, this blackened steel catwalk connects a mezzanine to a conference room. The catwalk includes cast glass lenses imbedded in the floor reminiscent of the cast iron sidewalk grates popular in lower Manhattan at the turn of the century. The China laser cut components were detailed in solidworks to fit together like a kit-of-parts that was assembled and installed over a weekend.

How Dan Shapiro created the most-backed game in Kickstarter history

So the idea is to have different components on discreet modules that are pretty tiny, some like the size of a postage stamp or maybe a little bit bigger. And they … And I think those arguments have some validity in them but I also think that this is …

Read more on Boing Boing

421 Pontiac: From Salvage Yard To Dyno

Now it's time to add the proper components to dress our 421 as though it originally appeared in 1964. For a majority of the components required to detail this engine, we turned to Ames Performance China Engineering, a company that specializes in Pontiacs.

Read more on Hot Rod Magazine

Precision Turned Components on eBay:

[wprebay kw=”precision+turned+components” num=”0″ ebcat=”-1″]

Check out these China turned components manufacturer images:

Messerschmitt KR200

Image by pedrosimoes7

MotorClássico, Lisbon, Portugal

in Wikipedia

The Messerschmitt KR200, or Kabinenroller (Cabin Scooter), was a three-wheeled bubble car designed by the aircraft engineer Fritz Fend and produced in the factory of the German aircraft manufacturer Messerschmitt from 1955 to 1964.

Messerschmitt, temporarily not allowed to manufacture aircraft, had turned its resources to producing other commodities. In 1952, Fend approached Messerschmitt with the idea of China manufacturing small motor vehicles.These were based on his Fend Flitzer invalid carriage.

The first of Fend’s vehicles to enter production at Messerschmitt’s Regensburg factory was the KR175. The title Kabinenroller means "scooter with cabin". While the Messerschmitt name and insignia were used on the car, a separate company, incorporated as Regensburger Stahl- und Metallbau GmbH, was created to manufacture and market the vehicle.

The KR200 replaced the KR175 in 1955. While using the same basic frame as the KR175 with changes to the bodywork (notably including wheel cutouts in the front fenders) and an improved canopy design,the KR200 was otherwise an almost total redesign. The rear suspension and engine mounting were reworked, and hydraulic shock absorbers were installed at all three wheels. Tire sizes were enlarged to 4.00×8.

Retailing for around DM 2,500, the KR200 was considered an instant success with almost 12,000 built during its first year. A maximum speed in excess of 90 km/h (56 mph)[8] despite a claimed power output of only 10 PS (7.4 kW; 9.9 hp) reflected the vehicle’s light weight.

In 1956, Messerschmitt was allowed to manufacture aircraft again and lost interest in Fend’s microcars. Messerschmitt sold the Regenburg works to Fend who, with brake and hub supplier Valentin Knott, formed Fahrzeug- und Maschinenbau GmbH Regensburg (FMR) to continue production of the KR200 and his other vehicles.

In 1957, the KR200 Kabrio model was released, featuring a cloth convertible top and fixed side window frames. This was followed by the KR201 Roadster without window frames, using a folding cloth top, a windscreen, and removable side curtains. A Sport Roadster was later offered with no top and with the canopy fixed into place so that the driver would have to climb in and out at the top of the car.

Production of the KR200 was heavily reduced in 1962 and ceased in 1964 as sales had been dropping for a few years. The demand for basic economy transport in Germany had diminished as the German economy boomed. A similar situation developed in other parts of Europe such as in the manufacturer’s biggest export destination, the United Kingdom, where sales were particularly affected by the increasing popularity of the Mini.

24-hour record run.

In 1955, in order to prove the KR200’s durability, Messerschmitt prepared a KR200 to break the 24-hour speed record for three-wheeled vehicles under 250 cc (15.3 cu in). The record car had a special single-seat low-drag body and a highly modified engine, but the suspension, steering, and braking components were stock. Throttle, brake, and clutch cables were duplicated. The record car was run at the Hockenheimring for 24 hours and broke 22 international speed records in its class, including the 24-hour speed record, which it set at 103 km/h (64 mph)

Messerschmitt Service Car.

Messerschmitt, and subsequently FMR, made factory-converted Service Cars to order for the automobile service industry. Similar in concept to the Harley-Davidson Servi-Car and the Indian Dispatch Tow, the Service Car had a detachable tow bar and clamp, a revised front suspension to accommodate the tow bar when in use, and a storage system inside the car to accommodate the tow bar when not in use. The service technician would drive the Service Car to the customer’s car and, if the customer’s car was drivable, attach the tow bar to the front of the Service Car, clamp the other end of the tow bar to the bumper of the customer’s car, and drive the customer’s car to the garage. When the service was complete, he would drive the car back to the customer while towing the Service Car, detach the Service Car from the customer’s car, and drive back to the garage. Approximately 12 were built; only one is known to exist at present.

Features

The KR200 incorporated several features unique to the KR line and its four-wheeled derivative, the FMR Tg500. Externally, the narrow body, the transparent acrylic bubble canopy and low stance were among the more obvious features.

Tandem seating

The narrow body, and corresponding low frontal area, was achieved with tandem seating, which also allowed the body to taper like an aircraft fuselage, within a practical length. 10 PS (7.4 kW; 9.9 hp) propelled the KR200 to around 105 km/h (65 mph). The consumption of the car was 87 mpg-imp (3.2 L/100 km).

The tandem seating also centralized the mass of the car along the longitudinal axis which, combined with the low center of gravity, low weight, and wheel placement at the vehicle’s extremes, gave the KR200 good handling characteristics. A more minor advantage of tandem seating was that it made an export version to countries that drive on the left unnecessary. An "Export" model was built, but this denoted a more luxurious trim level.

Bubble canopy

Messerschmitt Kabinenroller with Yılmaz Onay and Erol Keskin in Turkey. 1968

Entry to most KR models except the KR201 Sport Roadster and a corresponding Tg500 version was through a canopy door hinged on the right side of the vehicle. The door included all the windows (windshield, window frames on all but the Roadster models, folding top on Roadster and Kabrio models, and acrylic bubble on other versions) and the frame in which it was set, extending from the right side of the monocoque tub to the left. On Sport Roadster models, the canopy was fixed and there was neither a top nor any windows at all, only a tonneau cover.

KR200 Kabrio; the folding top replaces the bubble in this version.

The bubble top on the KR200 was simplified over that of the KR175 by the use of a larger curved glass windshield that formed A-pillars with the side window frames. This allowed the bubble to be simpler and more compact than the KR175 bubble, and it was consequently easier and less expensive to produce. The windshield wiper, manual on the KR175, was electric on the KR200.

Engine and transmission

The KR200 ran on a 191 cc (11.7 cu in) Fichtel & Sachs air-cooled single cylinder two-stroke engine positioned in front of the rear wheel, just behind the passenger’s seat. The engine had two sets of contact breaker points and, to reverse, the engine was stopped and then restarted, going backwards. This was effected by pushing the key further in the ignition switch than normal, whether intentionally or not. One result of this was that the KR200’s sequential, positive-stop transmission provided the car with the same four gear ratios available in reverse as in forward movement.

Controls

Instruments and controls of a KR201 Roadster

Apart from the dual-mode ignition, the KR200 had a steering bar reminiscent of that of an aircraft. Operated by pushing rather than by turning,[clarification needed] the steering bar was connected directly to the track rods of the front wheels, providing an extremely direct response best suited to small, measured inputs.[4][14] The gearshift lever had a secondary lever on it which, when actuated, would put the car in neutral regardless of what gear it had been in before, although the transmission would have to be shifted back to first before the car would be able to move from a standstill.

Unlike the KR175, the KR200 had a full set of pedals: clutch, brake, and accelerator. The brake pedal still operated mechanical brakes using cables.

Legacy

This section does not cite any references or sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed. (August 2010)

There are car clubs in Europe, the US, and elsewhere[where?] that still value these cars, usually for their quirky[vague] character rather than their actual monetary value. Nonetheless, some collectors[who?] will pay over €20,000 for a well-maintained "Schmitt".

Aftermarket reproduction parts are made for the KR200,[by whom?] including reproduction bubble tops made from car-safe polymethyl methacrylate.

Hotchkiss 864 (1937)

Image by pedrosimoes7

Cascais, Portugal

in Wikipedia

Hotchkiss cars were made between 1903 and 1955 by the French company Hotchkiss et Cie in Saint-Denis, Paris. The badge for the marque showed a pair of crossed cannons, evoking the company’s history as an arms manufacturer.

The company’s first entry into car making came from orders for engine components such as crankshafts which were supplied to Panhard et Levassor, De Dion-Bouton and other pioneering companies and in 1903 they went on to make complete engines. Encouraged by two major car distributors, Mann and Overton of London and Fournier of Paris, Hotchkiss decided to start making their own range of cars and purchased a Mercedes Simplex for inspiration and Georges Terasse, previously of Mors, was taken on as designer.

Early cars

The first Hotchkiss car, a 17 CV four-cylinder model, appeared in 1903. The engine of the 20 CV type C was heavily based on the Mercedes Simplex except that wherever possible it used ball bearings rather than plain ones (including the crankshaft) and except the Hotchkiss drive. Six-cylinder models, the types L and O followed in 1907.

The ball bearing engines lasted until the 30CV type X of 1910. In that same year Hotchkiss moved into a smaller car market with the 2212cc type Z.

With the outbreak of World War I, the factory turned to war production and a subsidiary plant was opened in Coventry, England. Car production resumed in France 1919 with the pre war types AD, AD6, AF and AG.

Inter war production

After an attempt to enter the luxury market with the AK, which did not get beyond the prototype stage, the company decided on a one model policy and introduced the Coventry designed AM in 1923. Later that year the Coventry plant was sold to Morris. Henry Ainsworth (1884–1971) and A.H. Wilde who had run it, moved to Paris to become general manager and chief engineer of the car division respectively.

In 1926 construction of the new factory in the Boulevard Ornano was completed and Hotchkiss bought a steel pressing company allowing in-house manufacture of bodies. The one model policy lasted until 1929 when the six-cylinder AM73 and AM80 models were announced.

The AM models were replaced by a new range in 1933 with a new naming system. The 411 was an 11CV model with four-cylinder engine, the 413 a 13CV four and the 615, 617 and 620 were similar six-cylinder types. The 1936 686, which replaced the 620, was available as the high-performance Grand Sport and 1937 Paris-Nice with twin carburettors and these allowed Hotchkiss to win the Monte Carlo Rally in 1932, 1933, 1934, 1939, 1949 and 1950.

Second World War

The armament side of the company and the body stamping plant were nationalised in 1936 by the Front Populaire government. The car company in 1937 took over Amilcar. With re-armament speeding up they also started making military vehicles and light tanks. When France declared war, in September 1939, Hotchkiss were sitting on a army order for 1,900 H35 and H39 tanks powered by six-cylinder motors of respectively 3.5 and 6 litres capacity, and at the time of the German invasion in May 1940 they were still working through the order.[1] However, as the military situation deteriorated the decision was taken, on 20 May 1940, to abandon the Saint-Denis plant which by now was fully concentrated on war production.[1] There was a disorderly evacuation, initially towards Auxerre and then Moulins and then further towards the south, as employees desperately tried to keep information on the military production out of the hands of the Germans.[1] However, the national capitulation implicit in the signing of the armistice on 22 June left these efforts looking somewhat irrelevant, and most of the employees drifted back in the ensuing weeks.[1] Two exceptions were the Commercial Director, Jacques Jacobsen and the English born General Director, Henry Ainsworth, both of whom managed to avoid capture and to leave France.[1] During the war, like many businesses in the occupied (northern) zone, the company was obliged to work for the occupiers and was engaged in the repair of military vehicles.[1]

In 1941 François Lehideux, then a leading member of the government’s economic team, called Jean-Pierre Peugeot and his General Director Maurice Jordan to a meeting, and invited them to study the possibility of taking a controlling share in the Hotchkiss business.[1] The suggestion from Lehideux derived from a German law dated 18 October 1940 authorising the confiscation of businesses controlled by Jews.[1] The Peugeot business itself had been operating, grugingly, under overall German control since the summer of 1940. In any event, in July 1942 Peugeot took a controlling share in the Hotchkiss business and towards the end of 1942 the names of Peugeot and Jordan were listed as members of the Hotchkiss board.[1] There is no evidence of any attempt to combine the operations of the two businesses, however: after the war Peugeot would relinquish their holding in Hotchkiss.

With liberation in 1944, Ainsworth returned and production restarted in 1946 with the pre-war cars, a light truck and a tractor.

Post war models

1955 Hotchkiss Anjou

After the war, car production resumed only slowly with fewer than 100 cars produced in each of 1946 and 1947, but by 1948 things were moving a little more rapidly with 460 Hotchkiss cars produced that year.[2] This volume of output was wholly insufficient to carry the company, although truck production was a little more successful with more than 2,300 produced in 1948,[2] and it was support from the truck volumes and from the Jeep based M201 that enabled the company to stagger on as a car producer slightly more convincingly than some of France’s other luxury car makers, at least until the mid 1950s. The cars that represented the business in the second half of the 1940s were essentially the company’s prewar designs. The 2,312 cc four-cylinder car was now branded as the Hotchkiss 864 while the six-cylinder car was badged as the Hotchkiss 680 with a 3,016 cc engine or as the Hotchkiss 686 with the 3,485 cc engine.[2]

The automobile range was modernised in 1950 and a new car, the four-door saloon Anjou, was available on the 1350 (renamed from the 486) and 2050 (686) chassis. The Anthéor cabriolet was added in 1952. In 1948 Hotchkiss had bought the rights to the Grégoire front-wheel-drive car and this car entered production in 1951 but was expensive. Sales in general were falling and in 1950 Ainsworth retired. The Peugeot family sold their interest in the company. Coupé and cabriolet versions of the Hotchkiss-Grégoire were announced in 1951, but sales did not improve, and production stopped in 1952 after only 247 were made.

Merger and closure

Hotchkiss merged with Delahaye in 1954 to become Société Hotchkiss-Delahaye, but car production stopped in 1955 to be replaced by licence built Jeeps. In 1956 the company was taken over by Brandt, a household appliance maker, to become Hotchkiss-Brandt, who were again taken over in 1966 by Thomson-Houston. Military vehicles were made until 1967 and trucks until 1971.

[edit]

A few nice cnc China turned parts images I found:

DC Universe Classics Wave 15 – Validus Wave

Image by fengschwing

Another wave complete. I told myself I was only going to cherry pick this wave and, surprise, surprise, I ended up getting every damn figure. I think this is also the first wave where I have all the variants too.

I knew I was definitely going to get Jack Knight (Starman is one of my all time faves) and Martian Manhunter is a must have, but I thought all the others were fairly uninteresting. Yeah, right! My daughter persuaded me to get Raven as she’s her favourite on the Teen Titans cartoon and, besides, I needed to finish that team off. Sinestro Bats is, admittedly, very cool and became kind of expensive in the UK so when I saw him going for the usual price in Forbidden Planet London, I had to snag him, after that, the ball started rolling I guess.

This is also the first wave where I’ve got over my ‘need’ to get every figure MOC, ‘regular’ Martian Manhunter and Ted Knight Starman were bought from eBay loose.

All in all, it’s actually a solid wave, Validus is an imposing beast of a CnC, there are some odd choices in there but even ‘the one with the stand’, Golden Pharaoh ends up being a fun figure with plenty of interesting features.

I still don’t think the world needs a Jemm action figure though…

There’s a real sense of closure with DCUC for me now, I’m closing in on an almost full collection and as the newer figures are going up in price and no longer offering CnC parts, I feel I’ll be done with it soon. It’s actually not a bad feeling, it will be nice to pursue something else for a change and not have to be so ‘must collect them all’ about something.

Or will I?

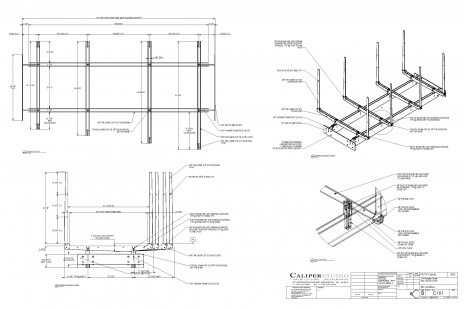

Catwalk example shopdrawing

Image by Caliper Studio

Designed for a multimedia design firm, this blackened steel catwalk connects a mezzanine to a conference room. The catwalk includes cast glass lenses imbedded in the floor reminiscent of the cast iron sidewalk grates popular in lower Manhattan at the turn of the century. The China laser cut components were detailed in solidworks to fit together like a kit-of-parts that was assembled and installed over a weekend.

cnc China turned components eBay auctions you should keep an eye on:

[wprebay kw=”cnc+turned+components” num=”0″ ebcat=”-1″]

Mining The Aisles: In-Store Experiences Will Render Troves Of Data, And Better …

What turned the trial into something even more promising was training the sales associates to pick up the tablet and use it while advising customers. The company … Email follow-ups can target the in-store browser with the kind of precision …

Read more on MediaPost Communications

Photonics tech dominates IOP innovation awards

Gooch & Housego's Torquay operation won for its development of acousto-optic components, which it sells under the “Fibre-Q” product line. According to the firm, the technology has created 23 jobs in the five years since it was launched, and generated …

Read more on Optics.org

3D Knee

There are a number of injuries that can affect different parts of the knee like the ligaments, cartilage and tendons. An ACL injury occurs when the anterior cruciate ligament, one of … Dr. Buch: In the old days if you came in under the age of 60 and …

Read more on NewsChannel5.com