A handful of good cnc turning machining images I located:

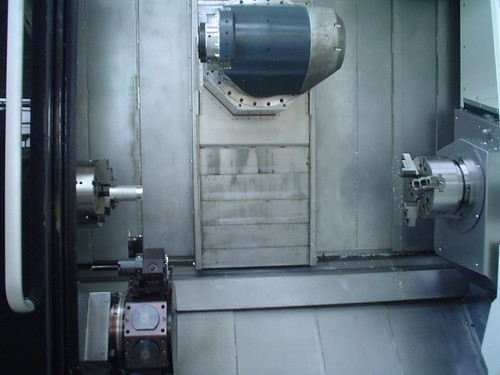

9-axis CNC turning/milling machine

Image by CatarinaMota

CTX gamma 1250 TC gildemeister @ Arts et Métiers – ParisTech

Aluminium Machining China

A handful of good cnc turning machining images I located:

9-axis CNC turning/milling machine

Image by CatarinaMota

CTX gamma 1250 TC gildemeister @ Arts et Métiers – ParisTech

Check out these milling and turning pictures:

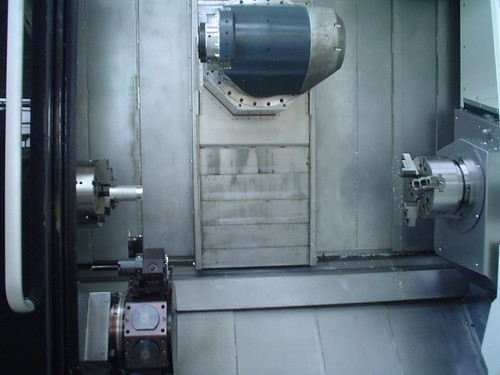

Mabry Mill Wheel Turning

Image by BlueRidgeKitties

This is anything I hadn’t observed yet: The waterwheel on the mill is turning again! This summer time, funding from the Blue Ridge Parkway Foundation allowed the National Park Service to restore the wheel, replace the supports and dredge the pond, which had overgrown with vegetation. It takes a little even though for the wheel buckets to collect enough water to make a turn, so it only does this every few minutes.

Some cool turning manufacturing photos:

Image from page 49 of “The velvet and corduroy market a short account of the a variety of processes connected with the manufacture of cotton pile goods” (1922)

Image by Net Archive Book Photos

Identifier: velvetcorduroyin00cook

Title: The velvet and corduroy sector a brief account of the numerous processes connected with the manufacture of cotton pile goods

Year: 1922 (1920s)

Authors: Cooke, J. Herbert

Subjects: Velvet Cotton manufacture

Publisher: London, New York [and so forth.] Sir I. Pitman & sons, ltd

Contributing Library: Smithsonian Libraries

Digitizing Sponsor: Smithsonian Libraries

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click right here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Prior to Image:

two,500 and 3,500 instances, it willbe realized that the sizing, to withstand the friction,is a matter for excellent care and experience. A variety of Types. In a plain kind of cloth, in the separa-tion of the warp threads for the passage of the weftbetween, the yarn is equally divided, i.e. just as manythreads are above as below the line of weft, and mechan-ically this is reversed for the next choose or line of weft,but in a velvet, fustian, or any cloth in which the weftis used to kind the face or pile, it is needed that asmuch as possible of the weft shall be laid on the surface,only enough warp threads being introduced to hold 34 VELVET AND CORDUROY Sector the weft and preserve it in its position when reduce, and herewe take advantage of the healds to Hft just as numerous,or as couple of, of the warp threads as may be necessary to holdthe weft, and the mechanism of the loom is adaptedto this end. The manner of varying the sequence in the liftingof the warp threads, and so producing a adjust in the V^arf) or

Text Appearing Following Image:

TwistX Cut right here following weaving. Diagram A PLAIN VELVET pattern and character of the velvet to be woven, willbe dealt with presently, and it will be shown how altera-tions in the lifting of the warp threads make thedifferent qualities of velvet to be described later on. A general concept of the intersection of threads to formthe pattern of a plain velvet is shown in Diagram A. The weft yarn to type the pile is normally made ofthe finest extended staple American cotton, although notinfrequently the good varieties of Egyptian or Soudancotton are used. The good quality have to be of the bestso as to turn out a excellent velvet piece, and to produce PREPARATION—SPINNING AND WEAVING 35 the excellent, soft and complete pile, so characteristicallybeautiful and rich hunting. It is important that theweft used must be spun as soft as feasible, with aslittle binding or handle of the fibres as is practicable,as considering that the pile mentioned is produced up of the ends oflarge numbers of definite and separate fibres, theymust be allo

Note About Photos

Please note that these pictures are extracted from scanned page images that may possibly have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original function.

Image from page 164 of “Manufacturing possibilities in the state of Washington” (1918)

Image by Web Archive Book Photos

Identifier: cu31924003609272

Title: Manufacturing opportunities in the state of Washington

Year: 1918 (1910s)

Authors: Washington (State). Workplace of the Secretary of State. Bureau of Statistics and Immigration

Subjects: Manufactures

Publisher: Olympia, Wash. Public printer

Contributing Library: Cornell University Library

Digitizing Sponsor: MSN

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Photos From Book

Click here to view book on-line to see this illustration in context in a browseable on-line version of this book.

Text Appearing Prior to Image:

itiesof quite high grade limestone, cheap fuel and a tremendous timberwaste from which to get the carbon. Turning to our all-natural supplies of obtainable nitrogen, thecoals of this state include, on an typical, about oneper cent, of their weight in nitrogen. When the coal is heatedto make coke or gas, the greatest element of this nitrogen can be Fcrtiliztr He.soiircfs 161 recovcTud in the kind of aninionium sulpliatc—a -aluahk for-tiliztT niatiTial. The gas functions of our larger cities are now coUeetino- niaiivtons of this nitrogen, but in the eoke ovens in the State ofWashington great quantities of valuable nitrogen components arebeing wasteil. Kventuallv, in this state, as is now being exten-sively (lone in Germany, coal will be distilled for the nitrogenand the useful oils and waxes. Some of oiir coals appear partie-ularlv adapted to this use. FISH WASTE. Washingtons greatest contribution to the nitrogeiiois fer-tilizer su[)plv is in the type of dried and treated fish scrap or

Text Appearing Soon after Image:

eutl-lisli packin.ii plant. fish guano. The greatest component of this guano is supplied byth< whaling businesses. 1 organization was formed for the pur-pose of working up dog fish and other worthless fisli. The Pacific Merchandise Company of Seattle and Port Town-send is functioning up the worthless fish as well as salmon canneryuaste. Appioximately 1,000 tons of ready fish fertilizer istlieii annual output. 3 and si.x-tenths tons raw fish makeone ton fertilizer, this containing about 11 per cent ni-tiogeii and 14 per cent bone phosphate. For years the salmon canneries threw away a trcinendoustonnage of scrap—some 40 or 50 })er cent of the weight of the 16!^ Manufacturing Opportunities in Washington fish—liuads, fins, viscera, and so on. These days, considerably of this scrap issaved and, when appropriately treated, forms a extremely fine fertilizermaterial containing both nitrogen and phosphorus. Processeshave been created whereby it is possible for cannery men topartially remedy their scrap and colle

Note About Images

Please note that these photos are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations might not completely resemble the original operate.

At Uncover 2015, Mazak debuted new technologies for CNC control, remote …

… machine builder's North American manufacturing headquarters. More than 30 machines, most featuring Mazak's Smooth technology, performed cutting demonstrations of parts via multi-tasking, Hybrid multi-tasking, five-axis, milling and turning techniques.

Study far more on Manage Design

See Huge Millturns Machining in Michigan

Until lately, U.S. shops interested in seeing huge WFL turn-mills in action (the firm refers to them as “millturns”) basically had two possibilities. The initial would be to have a … The M35 has a milling head supplying -110 to +110 degrees of B-axis …

Study much more on Modern Machine Shop (weblog)

Some cool cnc turning machining images:

Black Widow – Christopher Allison Photography –

Image by christopherallisonphotography

Christopher Allison Photography

619-368-2202

ALL Pictures ARE COPYRIGHT PROTECTED & Obtainable FOR Buy OR LICENCING

The Original Black Widow restored by Richard Riddell

Built in 1952

“THE BLACK WIDOW” Builders: Wally Olson (1952), Bill Scott (1954) and Richard Riddell (2005) The garage uncover of the century! How long have you been hot rodding vehicles–considering that the 1950’s? A lot of of us got started in the 50’s and 60’s. (For you actual old birds out there that bear in mind hot rodding “T” roadsters with Roto-Faze ignitions, Ruxtell two-speed rear axles, Riley 2-port heads and Laurel lowering kits, effectively what can we say you are a generation before us and we take our hats off to you ‘original’ hot rodders.) BUT for all of us “The Black Widow” is a severe piece of 1950’s hot rodding annals and a benchmark for the business! In an article in Hot Rod Deluxe, July 2008 entitled, “Tangled Web” the complete-story of Richard Riddell’s quest to restore the original Black Widow had its public debut. Hot Rod Deluxe reported the car’s winning the 2008 Grand National Roadster Show which was a dream come true, taking “Best Early Altered T Roadster”. (See also Rod and Custom, June 2008.) It was also a contender for the Bruce Meyer award at the ‘Grand Nats.’ Why do guys like Richard Riddell (and the rest of us) commit years (3400 hours in Richard’s case) restoring a car we located in a barn? Answer: ‘For the really like of the sport!’ All of us keep in mind some other automobiles with similar names, for instance the ‘Black Widow’ Monogram model automobile (“1/24 scale model/Ford ‘T’ Pickup Rod/removable top” by Mattel top quality hobby kits). Also, we remember Common Motors/Chevrolet coming out in 1957 with their very first racing version Chevy called “The Black Widow.” But predating each of these historic cars is the “The Black Widow” built by Wally Olson to help hold his children out of difficulty in 1952 and initial débuted in Hot Rod magazine, September 1954 in an write-up entitled, “Lil’ Beau T”, which study, “Wally Olson, Fresno, California, automotive machinist, is the lucky owner and builder. Duane Taylor was referred to as in for the body perform.” It added as to why he constructed the auto, “What with so considerably current upheaval in the teen-age ranks, Wally figured that a confident-fire way to eliminate these totally free-time, practically nothing-to-do troubles would be to interest them (his 9 and 12 year old sons) in a rod. So far the notion has worked like a charm.” In time the family members moved on to other projects and Bill Scott bought the car and redid it with fenders, headlights and all the stuff to make it ‘street legal’—as we employed to contact it! The very first documentation of the car becoming known as “Black Widow” is discovered in the magazine Rodding and Re-styling, August 1957 concern. That write-up reported Bill Scott’s alterations to Wally Olson’s vehicle, “The front finish was revised to incorporate a tubular axle and tube shocks. The new owners also equipped the auto with a new power plant. The original mill is a ’41 Merc bored out .100 inch over stock, ported and relieved…includes eight.5-to-1 Offenhauser heads, a Weber full-race cam, and an Evans three-caberator manifold.” [Note: The several engines that have been housed in this auto later varied see final Merc construct information under.] Don’t you adore the sound of that “ported and relieved” and “full-race cam”—when’s the final time you used those terms? By the time the 1959 Hot Rod Annual was published the vehicle-title stuck for all time “The Black Widow.” Riddell’s two-Year Renovation! According to extended time race auto builder Richard Riddell’s log he states, “Sometime in 1955 Wally sold his roadster to Bill Scott. Bill once again named on Duane Taylor to turn the car into a bonified street rod. With the extra of windshield, head lights, tail lings, and fenders it was finally capable to jump into his tiny Hot Rod and go crusin’. The pin stripping was accomplished by none other than Dean Jefferies with the familiar cobweb and spider on the turtle deck.” He reports that the car’s initial win was “…a 5 foot trophy at the Sacramento AutoRama in 1957 for ‘Best Roadster’. Yes, Bill’s auto was having the time of its life becoming 1 of the ideal looking early California street roadsters of all time.” Richard states, “Bill Scott died about 1987…for many years the vehicle languished…getting worse and worse…as is so frequently the case for old Hot Rods.” The garage uncover in 2005 notes, “At a glance the roadster didn’t appear that poor.” But the Naugahyde and carpet had been shot, fenders, original wheels and hub caps to name a few difficulties for the however to commence restoration. Riddell notes, “Under a somewhat decent physique and paint job lurked a mess that went beyond your worst nightmare.” He adds, “I began wondering how I could salvage this little beauty in the rough. Not that several individuals have restored an old Hot Rod but, these who have know what I’m talking about. It is a lot tougher than building a rod from scratch. But the roadster was begging to be restored and I’m glad that I was selected to do it.”and#9472Richard died shortly right after finishing the project but happily he was able to see “The Black Widow” win the ‘Grand Nats’ and have a feature center-spread post in Hot Rod Deluxe. Here are a handful of of the Riddell-engineered refinements to this original vehicle. and#61692 Recessed pockets had to be built in the frame rails to accept the front motor mounts which double as water pumps. and#61692 New front radius rods were built out of heavy wall chrome-moly tubing. The original ones had been so poorly made that they have been unsafe. and#61692 The correct master cylinder banjo fitting was not obtainable so, he fabricated a new a single from scratch. and#61692 The tooling mandral had to be CNC machined to facilitate metal spinning new brass tail pipe finish bells. Hey would you agree? Hot rodding is an art type and some Hot Rod Artists have mastered the craft and Richard Riddell is 1 of them!!! Reconstruction points of interest: and#61656 Original steel body and doors welded shut and#61656 ‘42 Merc 274 c.i flathead (current engine) and#61656 ’39 Lincoln-Zephyr tranny and#61656 ’34 Ford rear with Halibrand fast-adjust center and enclosed drive shaft and#61656 ’39 Ford hydraulic brakes all about and wide “5” 16-iunch wheels and caps and#61656 ’37 Ford tube axle and#61656 Engine by RPM Machine and#61656 Chrome by Ace Plating and#61656 Frame accomplished by Capps Powder Coat and#61656 Physique/paint by Showtime Customs and#61656 Upholstery by Brents Why is the automobile becoming sold? To quote his wife Pat, “Unfortunately, Richard passed away on March 18, 2008 and will not get to enjoy seeing the new owner drive away with a piece of automotive history.” Richard’s loyal wife Pat grew up around racing considering that she was 9 years old. Her maiden name was Rodriguez. If you grew up at Lion’s Dragstrip, as she did, you could bear in mind her father’s rail? He and his brother ran an old prime alky rail beneath the name “Rodriguez Brothers”. Pat mentioned, ‘As I was developing up I frequently wondered how I would ever meet someone to marry, because all that our loved ones ever did was go to the drags. Then one particular day Richard came along and met me at the Winternationals.’ Nicely the rest is history. For Pat soon after Richard’s death there are just as well many memories attached to all the memorabilia, race automobiles and hot rods in their storage—she would like to sell “The Black Widow” to some deserving hot rodder. Terms of sale: 5,000.00. Please get in touch with Don Burdge at DreamRodLocator or call him at 619.804.8033. You need to get in touch with me before Leno does! We have hundreds of added photos and numerous 50’s and present magazine articles available to seriously interested purchasers.

A few nice milling turning pictures I discovered:

The Quays, Wicklow, Co. Wicklow

Image by National Library of Ireland on The Commons

To finish this week we turn to matters maritime! The quays in Wicklow as we could only envision them. That wee ship is a good neat vessel and clearly nicely cared for OR brand spanking new?

Niall McAuley Was operating overtime nowadays, he supplied all the needed mapping information and manages to convincingly narrow the date range to between 1905 and 1912.

patrick.vickers1 knows the river here very nicely and tells us "The berth shown is exactly where the an old Brixham schooner utilized to be. Probably much better identified as the Susan Vittery, ex Brooklands. A record holder on the fruit run from the Azores, sunk in a gale in 1953 close to the Tuskar. When the tide was going down my grandfather and other individuals use to rake for mussels on the reduce arches of the river. The scene shown does not appear a lot distinct than seventy years ago !

Photographer: Robert French

Collection: The Lawrence Photograph Collection

Date: between ca.1905 – 1912

NLI Ref: L_ROY_09470

You can also view this image, and several thousands of other folks, on the NLI’s catalogue at catalogue.nli.ie

Kungsparken, Malmö, Sweden

Image by Maria Eklind

Spring 2014

A couple of nice turning components pictures I discovered:

Utilizing the metalwork lathe, turning down, taper turning, drilling, knurling and threading utilizing taps and dies.

Image by Jordanhill School D&T Dept

We find that Craft & Design and style pupils frequently have difficulty remembering the sequence of operations involved when producing a straightforward screwdriver deal with. These photographs depict this process.

We begin with the preparation of the 25mm aluminium blank. After this the blank is held in the three jaw self centering chuck. A series of turning operations is then carried out. For the following we set a higher spindle speed and utilised a slow feed speed for greatest benefits. Shown right here we show facing off. Then turning down or parallel turning. Next taper turning. Following that the Slocombe bit or centre bit is mounted in a Jacob’s chuck and a pilot hole is drilled. A HSS twist drill or jobber bit is then mounted in the Jacob’s chuck and a blind hole is drilled to a depth of 30mm. The depth gauge is employed to judge this.

Taps and dies are used to cut the internal thread on the screwdriver blade and the internal thread on the deal with.

Ultimately both components are assembled and the manage is knurled or provided a textured grip pattern. This is completed at a extremely low spindle speed and a slow automatic feed speed.

Element Components for a Custom Slitting Saw Holder

Image by tudedude

Getting purchased some stained but sharp slitting saw blades. There is a need to make a Blade Holder to suit.

The steel blanks are two.25" and have been turned on the faces soon after cutting off.

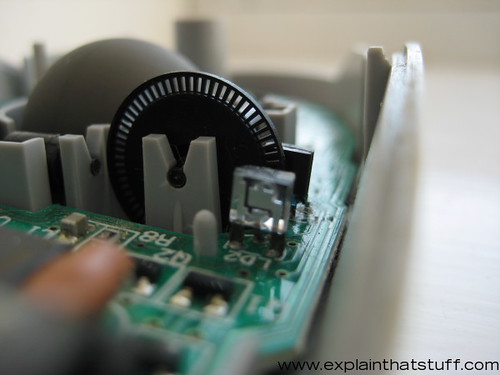

How a ball pc mouse functions

Image by explainthatstuff

Here’s a closeup of the mechanism that permits an old-style ball mouse to detect your hand movements. There’s a light beam operating among the transparent square (an LED-style light emitter) and the black square (a photocell/light detector). As you move your hand, the mouse ball moves too. It pushes against a roller that turns the spoked wheel, breaking the light beam repeatedly. Counting the quantity of occasions the beam is broken provides a precise measurement of how far your hand has moved.

This photo is from our write-up on how pc mice function.

For a bit more context, see the photo of the very same mouse taken from overhead.

Our images are published below a Creative Commons Licence (see opposite) and are cost-free for noncommercial use. We also license our pictures for industrial use. Please contact us straight by means of our internet site for a lot more particulars.

A couple of nice turning parts photos I found:

right here are some berries I made for skynet to make it feel far better for starting globe war iii

Image by harold.lloyd

So SKYNET got all mad because it got hacked from China and now China will get all mad back and people will point and say angry items and frown and sooner or later the computers will take more than and bomb us all to bits until John Connor requires more than and SKYNET is destroyed. Till then? Please take pleasure in the berries.

Boom! go the berries. Boom!

Anatomy of a huey

Image by psiaki

full breakdown pics rolling out in the next handful of days. I didn’t mean to "advertise" this, but after I was completed taking it apart I could resist taking this image and I thought it turned out quite good.

for any questioning, it tends to make this helicopter when put together….correctly.

County eyes income bonds to assist Wonderful Plains

To pay for deep milling and a 4 inch overlay of four.5 miles of main roads to handle semi trucks for industry would price $ 1.eight million, and an additional $ 1 million to address the five miles of secondary roads, leading to the businesses. There are also 17 …

Read more on Parsons Sun

Mazak Integrex i-100 Bartac-S

The Integrex i-one hundred Bartac-S has two turning spindles and a milling spindle for complete five-axis machining and Accomplished In A single operations. The primary spindle employs a 15hp integral motor spindle with maximum spindle speeds of 2,000rpm and a massive four.four" spindle …

Study more on Today’s Health-related Developments

MILLING: Metso expands Megaliner to mill heads

HELSINKI, Finland – The new Metso lightweight Poly-Met Megaliner™ for grinding mill heads gives the identical benefits as Metso's original Megaliner – namely secure installation and maximized availability. Like Metso's other Megaliners, this newest …

Study a lot more on Canadian Mining Journal

A handful of good precision turning and machining pictures I identified:

Unscrewing the Chuck

Image by tudedude

Very carefully unscrewing the 3 jaw chuck counter clockwise

Additional info at:

www.tudedude.co.uk/workshop/Lathe/3 Jaw Chuck.html